Universal Materials Testing Systems - Electromechanical

A universal materials testing system is a versatile machine used to measure the mechanical properties of materials under various forces, including tension, compression, flexure, and shear. These systems are called "universal" because they can test different materials (metals, plastics, ceramics, composites, etc.) and perform multiple types of mechanical tests.

Key Functions:

- Tensile Testing: Measures how a material reacts when stretched, providing data on strength, elongation, and modulus of elasticity.

- Compression Testing: Measures how a material behaves when compressed, showing properties like compressive strength and deformation.

- Flexural Testing: Measures the material's behavior when bent or flexed, often used for materials like plastics and composites.

- Shear Testing: Determines how a material reacts to forces that cause one part to slide relative to another.

Main Components:

- Load Frame: The structure that holds the sample and applies forces.

- Load Cell: Measures the force applied to the material.

- Crosshead: Moves up and down to apply tension or compression.

- Grips or Fixtures: Hold the material securely during the test.

- Control and Data Acquisition System: Manages the testing process and records data.

Instron is the world-leading manufacturer of universal testing machines, offering both electromechanical and hydraulic-powered systems. These machines are capable of performing a wide range of static tests, including tensile, compression, bend, peel, tear, shear, friction, puncture, and other mechanical tests. For the Electromechanical system, Instron has 2 main tiers, the 3400 and 6800 series.

Instron's 6800 Series Universal Testing Systems

The 6800 series Universal Testing Machines are designed to perform tensile, compression, flex, peel, puncture, friction, shear tests, and more. The systems are compatible with hundreds of grips and fixtures found in Instron’s expansive accessories catalog, with specific configurations designed to perform the most popular tests specific to the biomedical, automotive, consumer electronics, and raw materials industries.

The NEXT GENERATION 6800 Series universal testing systems range in capacity from 500 N to 300 kN and provide exceptional performance with unparalleled accuracy and reliability. Offering up to 5 kHz data acquisition and 0.5% accuracy down to 1/1000th of load cell capacity, the 6800 Series offers ultimate flexibility for any testing need.

The Instron 6800 Series represents the pinnacle of universal testing systems, designed to meet the demands of modern materials testing with enhanced precision, flexibility, and ease of use. Building on Instron’s legacy of engineering excellence, the 6800 Series offers advanced features and capabilities that cater to a broad range of industries, from aerospace to biomedical research.

Unmatched Versatility and Power

Instron's 6800 Series is an electromechanical powered system, capable of performing a wide variety of mechanical tests, such as:

- Tensile Testing: Accurately measures material properties like strength, elasticity, and elongation.

- Compression Testing: Determines how materials react under compressive forces, revealing properties like deformation and failure points.

- Bend Testing: Analyzes the material’s behavior when subjected to flexural forces.

- Peel and Tear Testing: Critical for evaluating the strength and integrity of adhesives, films, and packaging.

- Shear Testing: Examines how materials respond to forces that induce sliding between layers.

- Puncture and Friction Testing: Evaluates how materials behave under concentrated loads or surface friction.

This versatility allows the 6800 Series to test a wide range of materials, from metals and plastics to composites, textiles, and biomaterials.

Key Features of the 6800 Series

- Precision and Accuracy: The 6800 Series offers market-leading precision, with measurement accuracy that exceeds international testing standards (ISO 7500-1 and ASTM E4). With force capacities ranging from as low as 500 N to 300 kN, these machines are built to deliver highly accurate and repeatable results, even in the most demanding applications, with a loadcell class of 0.5% and a loadcell range of 1/1000.

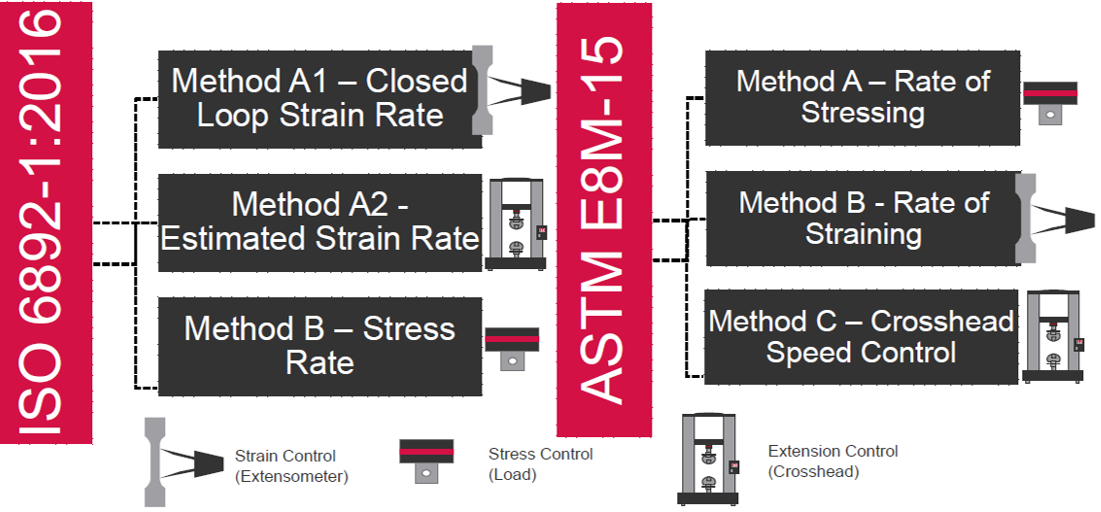

- Advanced Control and Software: Equipped with Instron’s latest Bluehill® Universal software, the 6800 Series offers a powerful yet intuitive interface for test control and data analysis. The software integrates seamlessly with a wide range of testing protocols, enabling users to customize tests and workflows according to specific needs. It also offers advanced data export options and test automation capabilities, improving productivity and efficiency in research and quality control environments. A fully synchronized controller with a data acquisition rate of 5000 Hz synchronous on load, displacement and strain measurement channels. Additionally, Test Profiler allows users to program complex multi-step tests without needing to write custom scripts, saving valuable time in test setup. The 6800 series advanced controller assists you in performing tests with displacement, strain and load control meeting all standards' technical requirements.

3. Safety and Ergonomics: Instron’s 6800 Series is designed with user safety and convenience in mind. The system features:

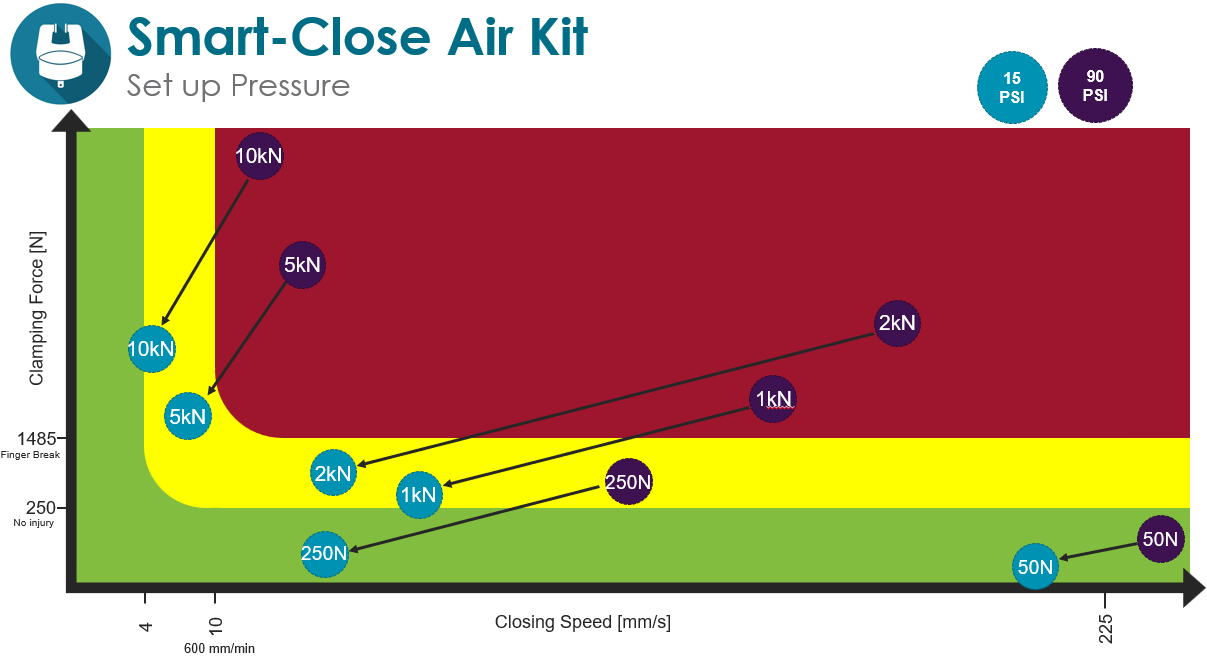

- Smart-Close Air Kit, which minimizes risks during the closing of pneumatic grips.

- Collision Mitigation Technology, which automatically stops the crosshead to avoid accidents in case of an unexpected obstruction.

- Auto Positioning automatically saves the correct fixture separation or starting location for each test method. This ensures that all operators run each test in exactly the same way, consistently across all shifts, every day.

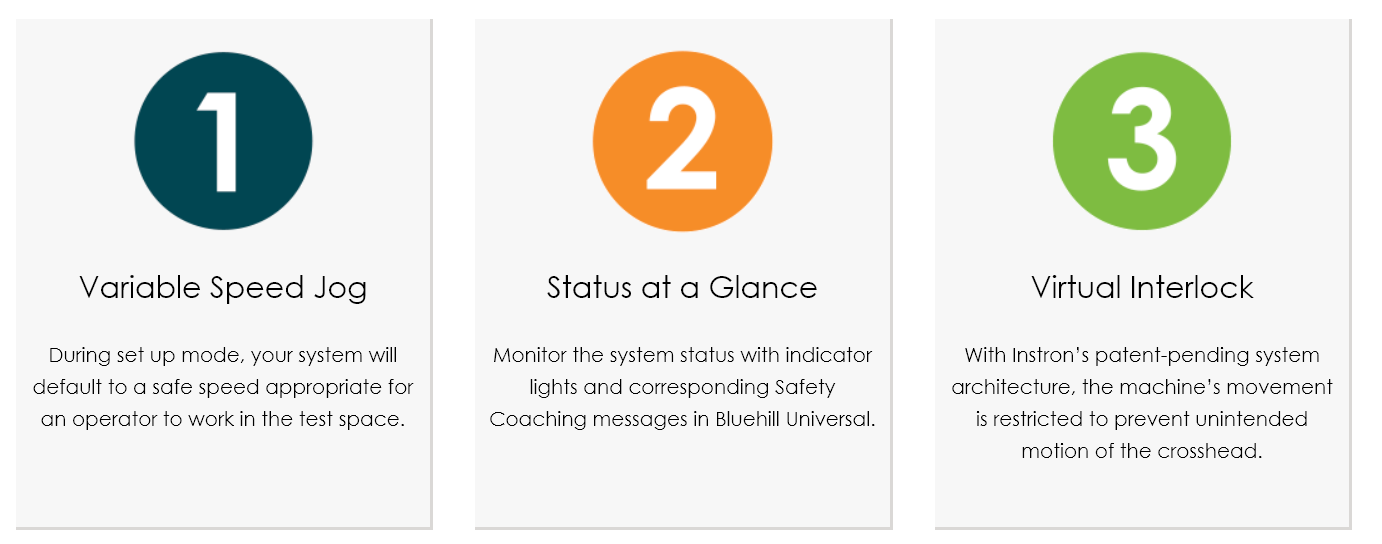

- Operator Protect This is the entire system architecture which divides the system operation into 4 modes: Disabled, Setup, Caution and Testing Modes. The presence of such mode makes the system safer to operates and prevents any accidents or action "made by mistake".

- Integrating this with the Built In Safety Coaching which incorporates the software that keeps reminding the operator with the critical tasks.

4. Efficiency Through Automation: Automation is a key driver of productivity in today’s testing environments, and the 6800 Series excels in this area. With options like automatic specimen measurement systems, auto-start grips, and load-string protection features, the system reduces human error, improves test repeatability, and significantly decreases setup time.

5. Built for Longevity: The Instron 6800 Series is engineered for durability, with components designed to withstand high-volume testing environments. Backed by Instron’s renowned global service and support network, users can expect exceptional performance and longevity from their equipment.

Applications Across Industries

The versatility of the 6800 Series makes it suitable for a wide range of applications across various industries:

- Aerospace and Defense: To ensure materials and components meet strict safety and performance standards.

- Automotive: For testing materials like metals, composites, and polymers along with the components used in the automotive industry used in vehicle manufacturing.

- Biomedical: Testing biomaterials, medical devices, and packaging materials to ensure compliance with regulatory standards.

- Construction Materials: Testing the strength and durability of building materials like sandwich panels, springs, and wood.

Why Choose the 6800 Series?

The Instron 6800 Series stands out for its superior accuracy, user-friendly software, and robust safety features, making it a trusted solution for research labs, quality control departments, and production environments. Whether you’re performing simple tension tests or complex multi-step mechanical analyses, the 6800 Series offers the reliability and performance that professionals worldwide expect from Instron. Instron’s 6800 Series is more than just a materials testing system—it’s an investment in quality, precision, and efficiency, ensuring that your testing processes are future-proof and able to meet the evolving challenges of material science and engineering.

Instron's 3400 Series Universal Testing Systems

The 3400 Series electromechanical universal testing machines offer the simplicity and performance needed for routine, standardized quality control tests and general-purpose mechanical testing.

The 3400 Series brings system controls closer than ever with its all-new operator panel. Enhance ergonomics and increase throughput by starting and stopping tests, jogging the crosshead, and returning to the starting position directly from the instrument.

Instron’s 3400 Series Universal Testing Machines are designed to meet the growing demands of materials testing in both research and industrial environments. Offering powerful capabilities with an intuitive interface, the 3400 Series is an ideal solution for performing basic mechanical tests such as tension, compression, flexure, peel, shear, and more. Built for users who need high performance and reliability, the 3400 Series delivers consistent and accurate results while improving workflow efficiency and ergonomics.

Key Features of the 3400 Series

- User-Friendly Operator Panel: One of the standout features of the 3400 Series is its enhanced operator panel, designed to bring system controls closer to the user. With this panel, operators can:

- Start and stop tests with ease.

- Jog the crosshead for precise positioning of the grips or fixtures.

- Return to the starting position quickly and efficiently after each test.

- High Accuracy and Flexibility: The 3400 Series offers highly accurate force measurements, meeting or exceeding industry standards such as ISO 7500-1 and ASTM E4. With load capacities ranging from 500 N to 300 kN, the system is versatile enough to handle a wide range of material types and sizes, including metals, plastics, composites, elastomers, textiles, and more. With a loadcell of a class 0.5% and a loadcell range of 1/200 of the maximum load capacity.

- Improved Ergonomics and Safety: The machine is designed with user comfort and safety in mind. Key features include:

- Smart Close Air Kit for pneumatic grips, reducing risks during operation.

- Collision Mitigation Technology, which automatically halts crosshead movement in the event of an unexpected obstruction.

4. Built for Longevity and Performance: The 3400 Series is engineered for durability, capable of handling high testing volumes over time without compromising performance. It is backed by Instron’s global support and service network, ensuring that users have access to world-class technical assistance and maintenance whenever required. Thanks to the AC Motor and the full performance envelope of the materials testing system.

- Packaging: Evaluating the strength, puncture resistance, and tear properties of packaging materials to ensure product safety during transit.

- Consumer Products: Testing the durability, flexibility, and strength of materials used in electronics, textiles, and appliances.

- Cables Testing: providing precise measurements of tensile strength, elongation, and durability, ensuring that cables meet industry standards for performance and safety, whether for the metal core or polymer insulation.

- Polymers Testing: delivering accurate results for tensile strength, elasticity, and fracture toughness, ensuring materials meet rigorous quality and performance standards, whether rigid or flexible polymers.

Why Choose the Instron 3400 Series?

The Instron 3400 Series combines precision, simplicity, and durability in a single system, making it the perfect choice for organizations looking to streamline their testing processes while maintaining high standards of accuracy and safety. With its enhanced operator panel, intuitive software, and advanced features like Collision Mitigation Technology, the 3400 Series is designed to make materials testing faster, safer, and more consistent.

Instron’s 3400 Series is a reliable, high-performing solution for any materials testing application, providing the tools needed to maintain quality, improve efficiency, and ensure consistent results across shifts and operators.

Integrating the Electromechanical testing machine with Instron's range of accessories and Materials Testing and Data Analysis Software to meet all the testing standards and perform all the versatile testing applying all your international and internal standards along with all R&D projects without the added costs of having a module for each method (create your method yourself).

For the ease of use Instron has also made a library of methods with standards briefs that allows you to directly test or create your own method.

The below video is a seminar on how to use Bluehill Universal for your testing and incorporate its features with your technical requirements.