Automated Ultrasonic Defects Detectors Testing System

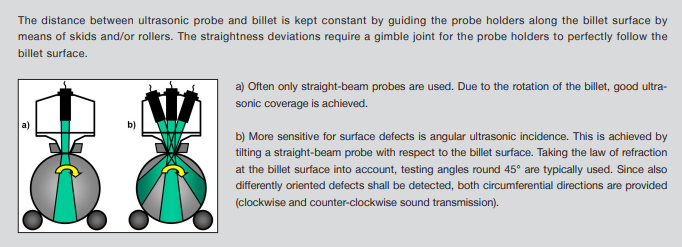

Ultrasonic Testing System ECHOGRAPH-ALPT/RPTS: Round Billets Testing

Product Description

The ECHOGRAPH-ALPT/RPTS system is a state-of-the-art ultrasonic testing solution designed specifically for the inspection of round billets, ensuring comprehensive examination of their entire volume. This system is particularly effective for billets with large diameters, typically ranging from 80 mm to 350 mm. Its design incorporates a portal or bridge mechanism, facilitating a robust and efficient testing process.

Operational Mechanics

The inspection process involves feeding the billets into the testing system, where they are set in rotation. This rotation is critical for achieving a thorough inspection. The probe holders, mounted on linear test carriages, move along the length of the bars, creating helical test tracks that maximize coverage. The probe holders are positioned atop the billets, utilizing a cardanic suspension system that ensures stable and consistent coupling with the billet surface.

Defect Detection

One of the standout features of the ECHOGRAPH-ALPT/RPTS system is its ability to employ various insonification angles. This versatility allows for the detection of defects located both in the core and just beneath the surface of the billets. The system is designed to provide a 100% cross-sectional coverage, ensuring that no potential flaws go unnoticed.

Key Facts

- Rotating Billet Inspection: Designed for billets with diameters ranging from 80 mm to 350 mm.

- 100% Cross-Sectional Coverage: Achieved through helical test tracks, ensuring complete inspection.

- Variable Number of Probe Holders: The system can be configured with a flexible number of probe holders based on throughput requirements, enhancing operational efficiency.

- Cardanic Suspension: The cardanic suspension of the probe holder ensures stable coupling, even on uneven surfaces, facilitating accurate measurements.

- Coupling Methods: The system supports both water jet and gap coupling techniques, allowing for adaptability based on specific testing tasks.

- Material References: The system is applicable for both steel and aluminum billets, making it a versatile choice for manufacturers.

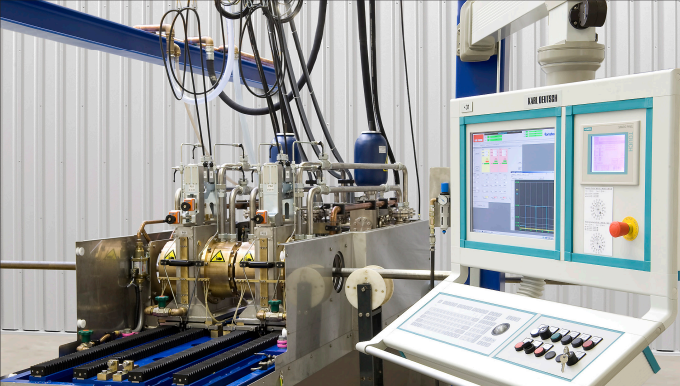

Ultrasonic Testing System ECHOGRAPH-HRPR: High-Speed Tube Testing

Product Description

The ECHOGRAPH-HRPR system is a cutting-edge ultrasonic testing solution specifically designed for high-speed inspection of tubes. Renowned for its efficiency and minimal mechanical wear, this system has been a trusted choice in the industry for decades. Notably, it operates without rotating mechanical components, which enhances its durability and reliability.

Operational Mechanics

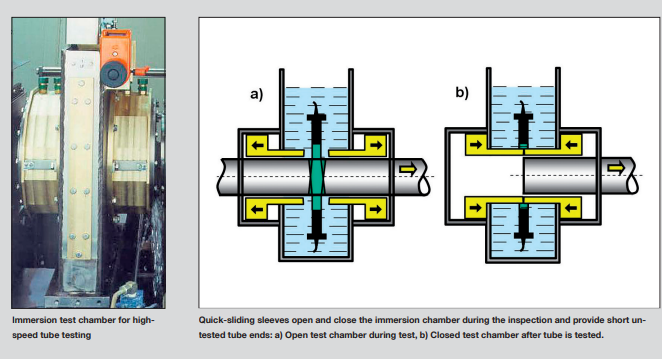

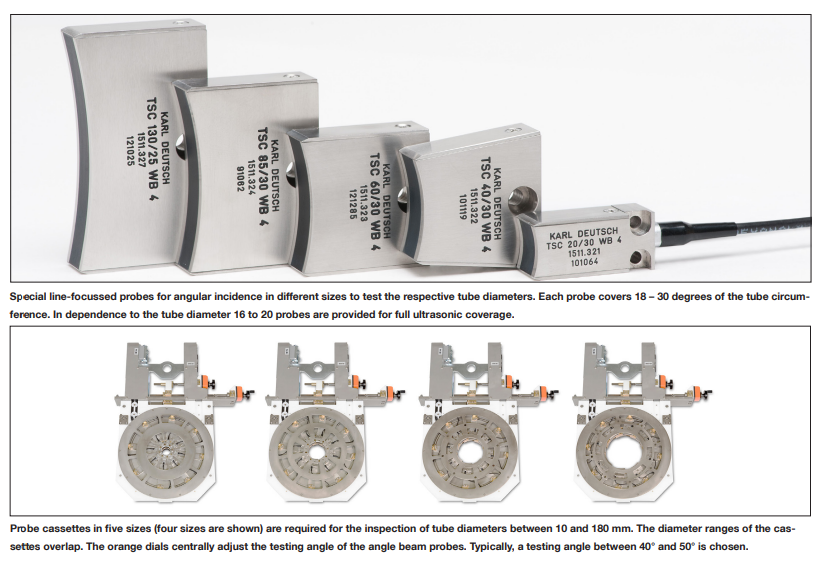

Tubes with diameters typically ranging from 10 mm to 170 mm are conveyed linearly through the testing facility, ensuring a streamlined and rapid inspection process. The system employs immersion technology, where the section of the tube to be tested is fully submerged in water, allowing for superior sound transmission and defect detection.The design features a sealed water chamber and specialized probe cassettes that encircle the tube. This configuration provides comprehensive coverage without the wear associated with rotating probes, resulting in a virtually maintenance-free inspection system.

Testing Capabilities

The ECHOGRAPH-HRPR is adept at conducting longitudinal flaw inspections by insonifying the tube in both circumferential directions. This dual approach ensures accurate detection of potential defects. Additionally, the system can accommodate various probes for optional wall thickness measurements and transverse defect inspections, making it a versatile tool for comprehensive material evaluation.

Key Facts

- Fast Tube Inspection: Designed for tubes with diameters ranging from 10 mm to 170 mm, ensuring compatibility with a wide range of products.

- Linear Tube Conveyance: Capable of conveying tubes at speeds of up to 2 m/s, facilitating rapid inspection without compromising accuracy.

- Circular-Mounted Probes: The probes are mounted in cassettes that encircle the tube, enhancing coverage and detection capabilities.

- Immersion Technology Coupling: Utilizing immersion technology ensures optimal coupling and effective ultrasonic transmission for reliable testing results.

- Fast Changeover: The system is designed for quick changeover, allowing for efficient adaptation to different tube sizes and inspection requirements.

- Short Untested Ends: The ECHOGRAPH-HRPR minimizes untested ends, maximizing the length of the tube that can be inspected.

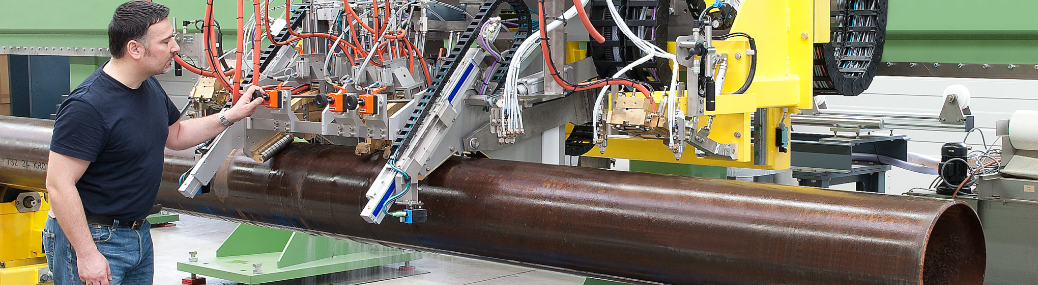

Ultrasonic Testing System ECHOGRAPH-SNHF: RF-Welded (ERW) Pipes

Product Description

The ECHOGRAPH-SNHF system is specifically engineered for the ultrasonic testing of radio-frequency (RF) welded pipes, a crucial process in ensuring the integrity and quality of these products. This system is designed to perform inspections both online, immediately after the welding process, and offline, once the pipes have undergone further manufacturing steps.

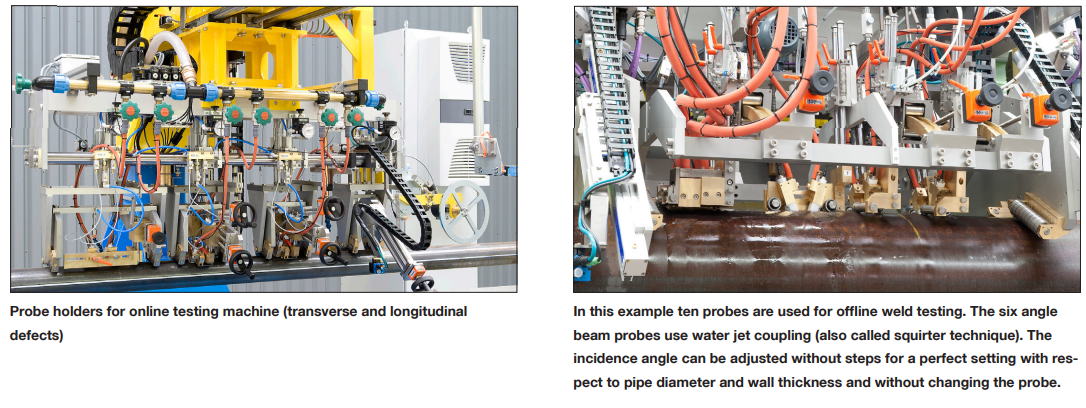

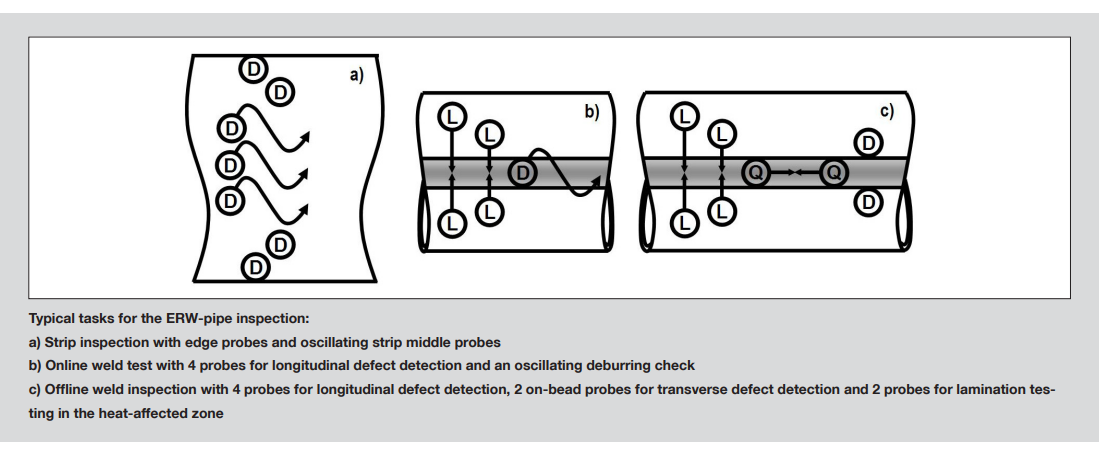

Online Inspection Process

In the online inspection stage, the weld seam of the still hot RF pipe is examined using ultrasonic testing immediately following the welding process. This is achieved through the use of a water jet coupling, which effectively prevents overheating of the probes, ensuring reliable measurements. The online testing facilitates real-time monitoring of the production process, enabling early detection of any potential issues.For longitudinal defect detection, angle-beam scanning is typically employed using four probes. This method allows for thorough inspection of the weld seam. Additionally, an oscillating vertical probe may be used to monitor the internal scraping of the pipe weld seam, further enhancing the accuracy of the inspection.

Offline Inspection Process

Once the endless pipe is sawn and subjected to various additional production steps, it undergoes an offline ultrasonic testing stage. This is usually conducted using a high-throughput inspection portal or an inspection bridge, designed to handle finished pipes efficiently. The examination can include a strip test of the tube body prior to welding or be integrated into the offline test for comprehensive evaluation.

Key Facts

- Testing of Longitudinally Welded RF-Tubes: The system specializes in inspecting RF-welded pipes to ensure quality and structural integrity.

- Typical Pipe Diameters: Capable of inspecting pipes with diameters ranging from 80 mm to 630 mm, accommodating various mechanical sizes.

- Dual Inspection Modes: Supports both online inspection of the endless tube and offline inspection of the finished product, allowing for thorough quality control at multiple stages of production.

- Longitudinal Flaw Inspection: Utilizes angle beam insonification for detecting longitudinal flaws, with additional inspection tasks based on specific requirements, such as scraping inspection and detecting laminations in the heat-affected zone, pipe body, and at the pipe end.

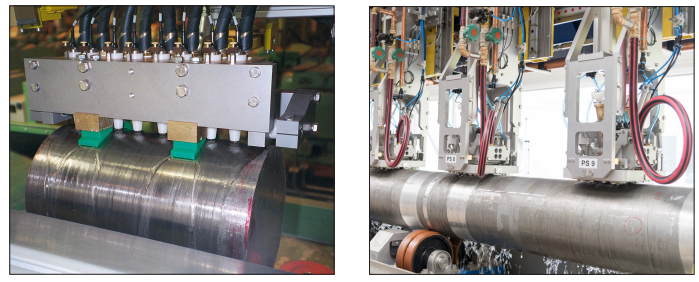

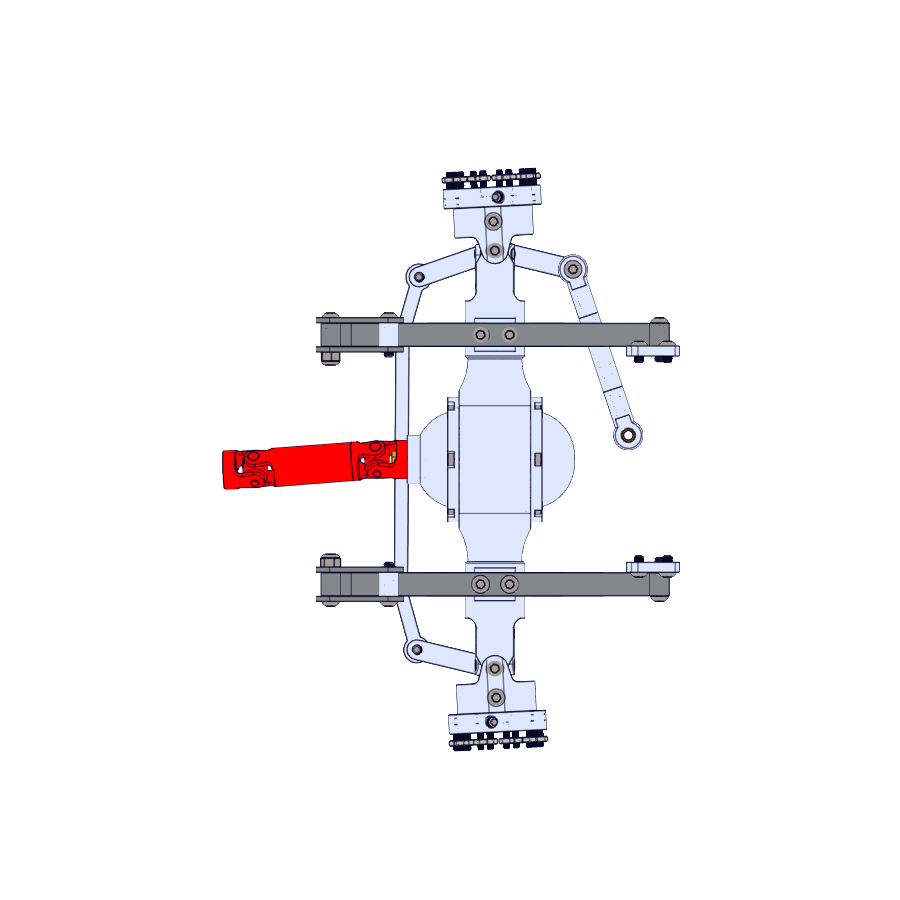

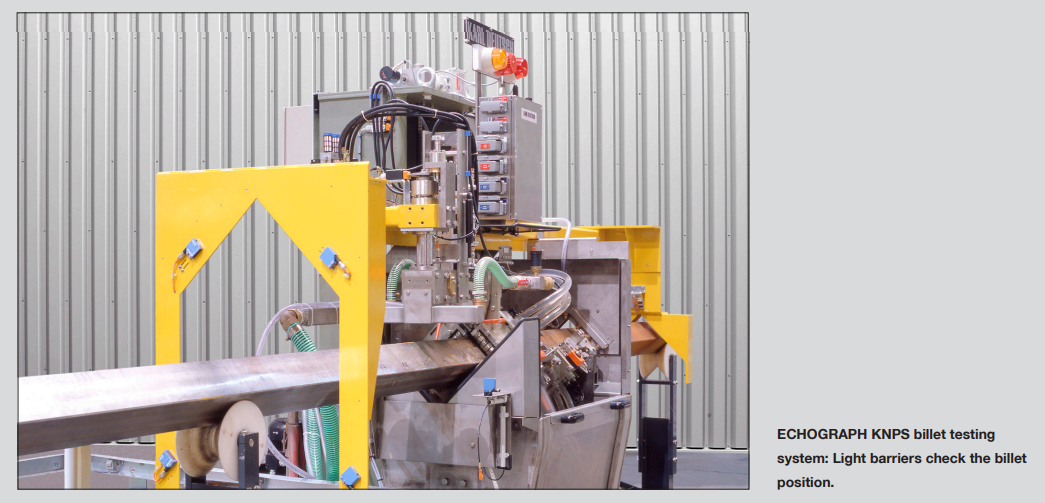

Ultrasonic Testing System ECHOGRAPH-KNPS: Billet Testing

Product Description

The ECHOGRAPH-KNPS system is specifically designed for the ultrasonic testing of round and square billets, typically produced through continuous casting techniques. With cross-sectional dimensions ranging from approximately 100 mm to 300 mm, this system ensures comprehensive inspection capabilities immediately after production.One of the standout features of the ECHOGRAPH-KNPS is its ability to scan slightly curved and twisted billets, thanks to gimbal-mounted probe holders that maintain optimal positioning during inspection. This flexibility enhances the accuracy and reliability of the testing process.

Ultrasonic Coupling Technology

The ECHOGRAPH-KNPS employs a reliable ultrasonic coupling method using a water jet. This technique allows for effective sound beam coupling, even with distance variations of several millimeters between the probes and the billet surface. The use of water jets minimizes wear on the probes and facilitates rapid changeovers between different profile dimensions, ensuring high coverage of the billet's cross-section.

Probe Configuration

For the inspection of square billets, the system utilizes a total of 28 probes, strategically divided among four probe carriers. This configuration allows for vertical insonification, ensuring thorough examination of the billet’s integrity. In contrast, for round billets, the inspection mechanics are adapted to use nine probes, with three focusing on the core area and six employing angle-beam insonification for near-surface inspection.

Key Facts

- Fast Billet Inspection: Capable of efficiently inspecting billets with diameters ranging from 100 mm to 300 mm.

- Linear Billet Conveyance: The system operates with linear billet conveyance speeds of 0.5 m/s to 1 m/s, optimizing throughput.

- Probe Variety: Utilizes between 9 to 28 conventional probes, depending on the shape and configuration of the billet being tested.

- Water Jet Coupling: Employs a squirter technique for coupling, ensuring low wear and easy adjustment for different billet profiles.

- Fast Changeover: The system is designed for quick adjustments to accommodate varying billet sizes, enhancing operational efficiency.

- Cardanic Suspension: This feature compensates for straightness tolerances, allowing the probe holders to maintain accurate positioning.

- Positioning Mode: Probe holders operate in a positioning mode, lowering or raising according to the specific billet being tested.

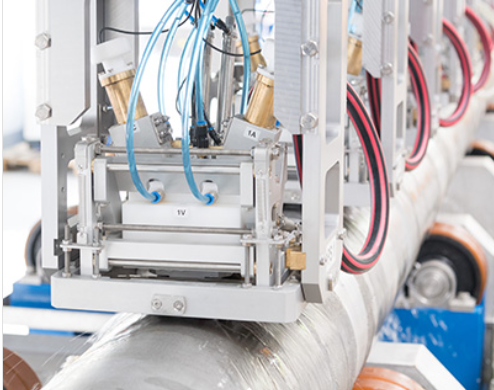

Ultrasonic Testing System ECHOGRAPH-STPS: Bar Testing

Product Description

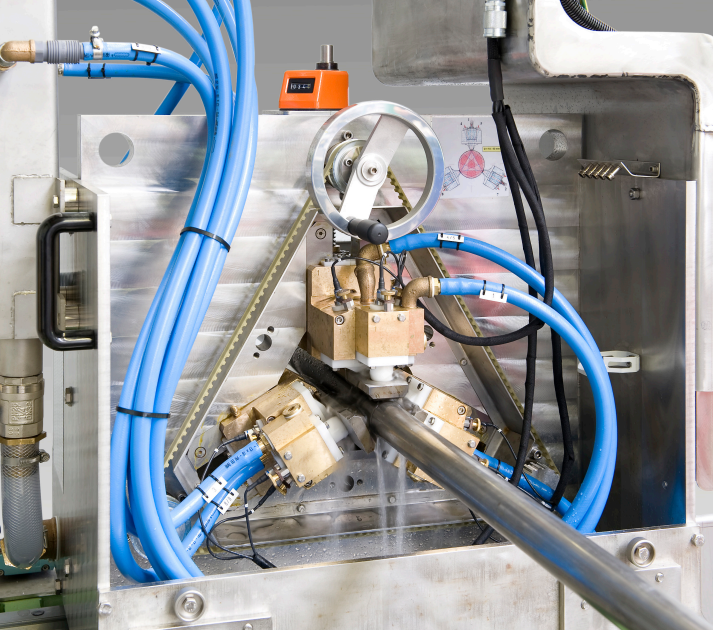

The ECHOGRAPH-STPS system is engineered for the rapid ultrasonic testing of bars, accommodating diameters ranging from 15 mm to 130 mm. This advanced testing solution facilitates linear transport of bars through the machine at speeds of up to 2 m/s, ensuring efficient inspection without sacrificing accuracy.The system's design incorporates compact mechanics that significantly reduce changeover times to approximately five minutes. This quick adjustment is achieved through the simultaneous calibration of all probe holders, streamlining the setup process.

Ultrasonic Coupling and Compensation

The ECHOGRAPH-STPS utilizes a water jet coupling method (squirters) to maintain effective ultrasonic contact without wear. This feature ensures consistent performance and reliability throughout the testing process. Additionally, the system is equipped to compensate for mechanical straightness tolerances of the bars, typically ranging from 1 mm/m to 2 mm/m, through a spring-loaded suspension mechanism for the probe holders. This capability makes the system particularly well-suited for testing black bars.

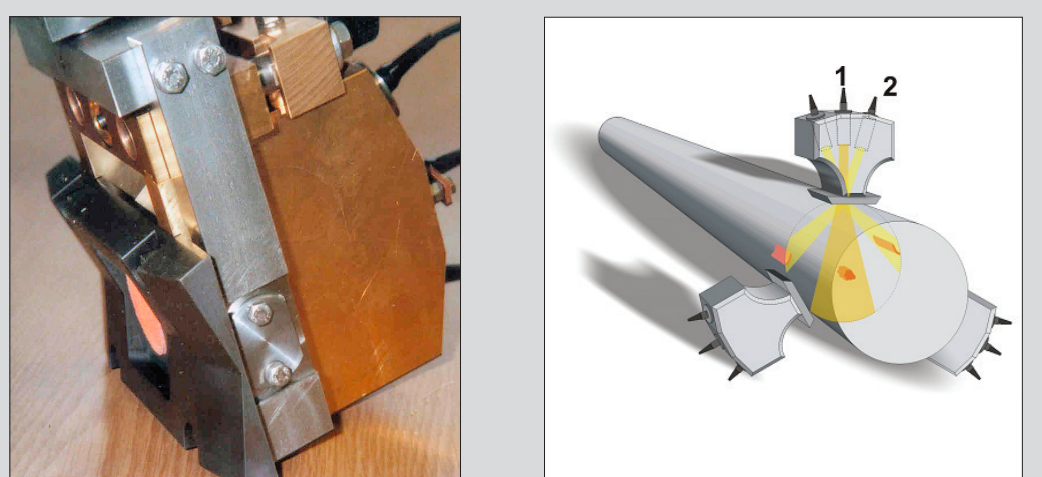

Probe Configuration

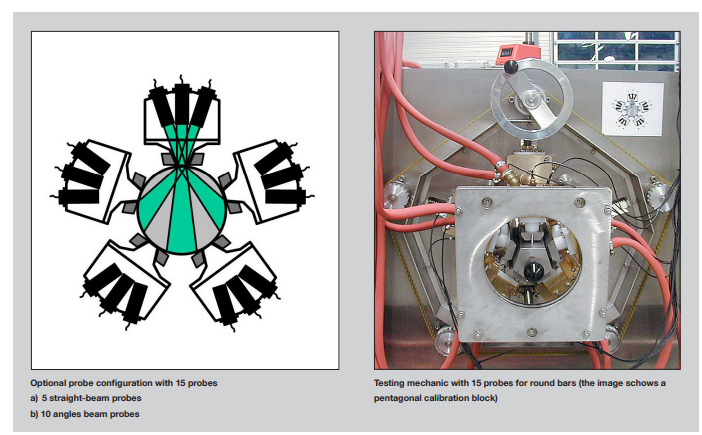

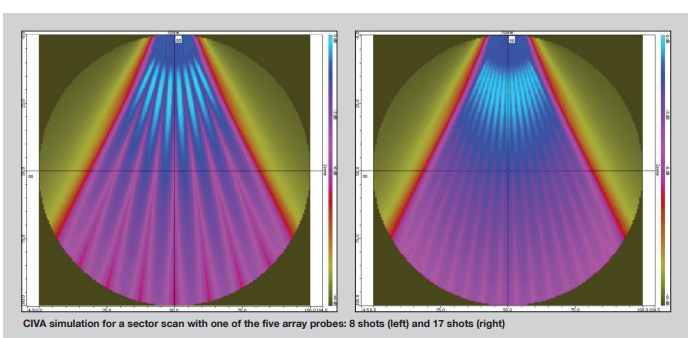

The conventional ECHOGRAPH-STPS inspection system incorporates between 3 and 15 probes, providing comprehensive coverage for thorough evaluation. For enhanced inspection capabilities, the phased array version, ECHOGRAPH-STPS-PAUT, utilizes five probes to achieve 100% volume inspection of the bar. This version employs overlapping sector scans with up to 20 shots per probe, resulting in a total of up to 120 parallel inspection channels. This advanced configuration allows for highly detailed examination of the bar's integrity.

Key Facts

- Rapid Bar Testing: Specifically designed for bars with diameters between 15 mm and 130 mm, ensuring quick inspection times.

- Linear Bar Transport: Capable of moving bars at speeds of up to 2 m/s, optimizing throughput in manufacturing settings.

- Probe Variety: The system can accommodate 3 to 15 probes in conventional setups, with enhanced capabilities in the phased array model.

- Water Jet Coupling: Utilizes a squirter technique for effective, wear-free ultrasonic coupling.

- Fast Changeover: Designed for minimal downtime, with quick adjustments for different bar sizes.

- Straightness Compensation: Features spring-loaded suspensions that accommodate straightness tolerances, maintaining probe accuracy.

- Short Untested Ends: Reduces the length of untested sections, increasing overall inspection efficiency.

Ultrasonic Testing System ECHOGRAPH STPS PAUT: Phased Array Testing of Bars

Application Overview

The ECHOGRAPH STPS PAUT system represents a significant advancement in the ultrasonic testing of bars, designed to provide rapid and comprehensive volume inspections. This phased array system is specifically tailored for bar diameters ranging from 15 mm to 130 mm, making it ideal for various manufacturing applications.

Product Description

The phased array version of the ECHOGRAPH STPS system facilitates fast 100% inspection of bar volume using five probes. These probes generate overlapping sector scans with up to 20 shots each, resulting in a remarkable total of up to 120 parallel test channels. This capability ensures thorough examination of the material, identifying any potential defects within the entire cross-section.Bars are efficiently transported through the testing system at speeds of up to 2 m/s, allowing for high throughput while maintaining accuracy. The mechanical design of the system is both simple and compact, enhancing operational efficiency.

Key Features

- Rapid Bar Testing: Suitable for bars with diameters from 15 mm to 130 mm, ensuring quick and reliable inspections.

- Linear Transport: Capable of moving bars at speeds of up to 2 m/s, optimizing production flow.

- Phased Array Probes: Utilizes five probes to create overlapping scans, enhancing detection capabilities.

- Water Jet Coupling: Employs a wear-free water jet coupling method, ensuring consistent performance without wear and tear.

- Fast Changeover: Designed for minimal downtime, with very short changeover times of approximately five minutes due to simultaneous adjustment of all probe holders.

- Compensation for Straightness Tolerances: The system features a spring-loaded suspension for the probe holders, compensating for mechanical straightness tolerances (typically 1 mm/m – 2 mm/m), making it especially effective for testing black bars.

- Short Untested Ends: Reduces untested sections, maximizing overall inspection efficiency.

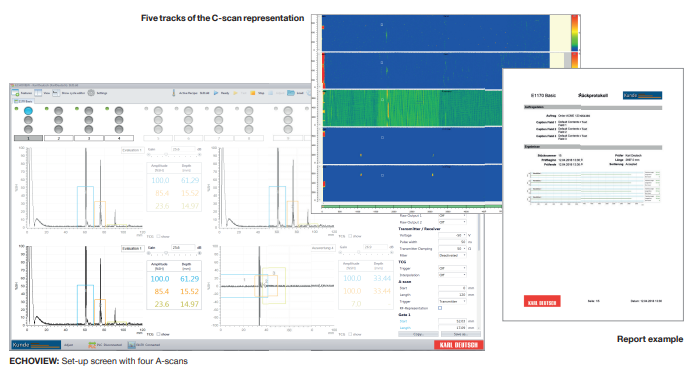

Multichannel Ultrasonic Testing Electronics: ECHOGRAPH 1170

Product Description

The ECHOGRAPH 1170 Basic is a sophisticated modular ultrasonic electronics unit designed to meet the demanding needs of modern ultrasonic testing. Housed in a compact 4HU 10″-module rack, the ECHOGRAPH 1170 offers flexibility and scalability, allowing users to equip the rack with a master module and up to three ultrasonic modules.Each ultrasonic module features four multiplexed channels, which can be configured independently for either TR (transmitter-receiver) or single-element probes. This modularity provides users with the ability to customize their testing setups according to specific requirements, enhancing the versatility of the system.The ECHOGRAPH 1170 boasts a maximum pulse repetition frequency of 8 kHz, which can be distributed among the four channels within each module. This allows for an average maximum pulse repetition frequency of 2 kHz, ensuring efficient data acquisition during testing.Additionally, one of the four channels in each module can perform measurements concurrently, and with multiple modules, parallel operation of channels is achievable. The master module plays a critical role in managing data from individual ultrasonic channels, configuring them, and controlling the timing program.For enhanced data analysis and visualization, the optional ECHOVIEW software tool enables function-oriented evaluations such as routine testing, strip chart displays, and C-scans.

Key Features

- Modular Configuration: Supports up to 12 channels per rack, allowing for scalable testing setups tailored to user needs.

- Standardized Modules: Similar 4-channel modules simplify spare parts stocking and maintenance.

- Versatile Gates: Three overlapping gates and two trigger gates enable simultaneous entry and back wall echo triggering or flexible back wall-to-back wall thickness measurements.

- Extended Measuring Range: Capable of measuring up to 5 meters, accommodating a variety of applications.

- Multiplex and Parallel Operation: Supports both multiplexed and parallel testing for greater efficiency.

- Advanced Compensation: Features analog and digital depth compensation (Time Corrected Gain - TCG) for improved accuracy, with triggerable options.

- High-Resolution Measurements: Wall thickness measurements achieve a resolution of 0.01 mm or better, ensuring precision in results.

- User-Friendly Interface: Easy-to-use cycle programming simplifies the testing process.

- Complete Solution: Optionally available as a self-contained PC system for a comprehensive ultrasonic testing solution.