Consumables

Grinding and Polishing Consumables: A Full Range for Every Need

Achieve the highest quality results with our comprehensive range of grinding and polishing consumables, designed to optimize your material preparation process. Whether your goal is to reveal the true structure of your specimen or to achieve acceptable results with minimal artifacts, our consumables provide reliable, accurate, and reproducible outcomes for any material and preparation requirement.

Why Choose Our Consumables?

- Proven Performance: Our consumables are backed by Struers' proven methods, ensuring you achieve valid and reproducible results every time.

- Optimized Compatibility: Protect your investment with consumables specifically designed to work seamlessly with your Struers equipment, maximizing performance and durability.

- Efficient Supply Chain: Minimize downtime and reduce inventory costs with our robust global supply chain, ensuring you have access to the right consumables when you need them.

Optimize Your Grinding and Polishing Process

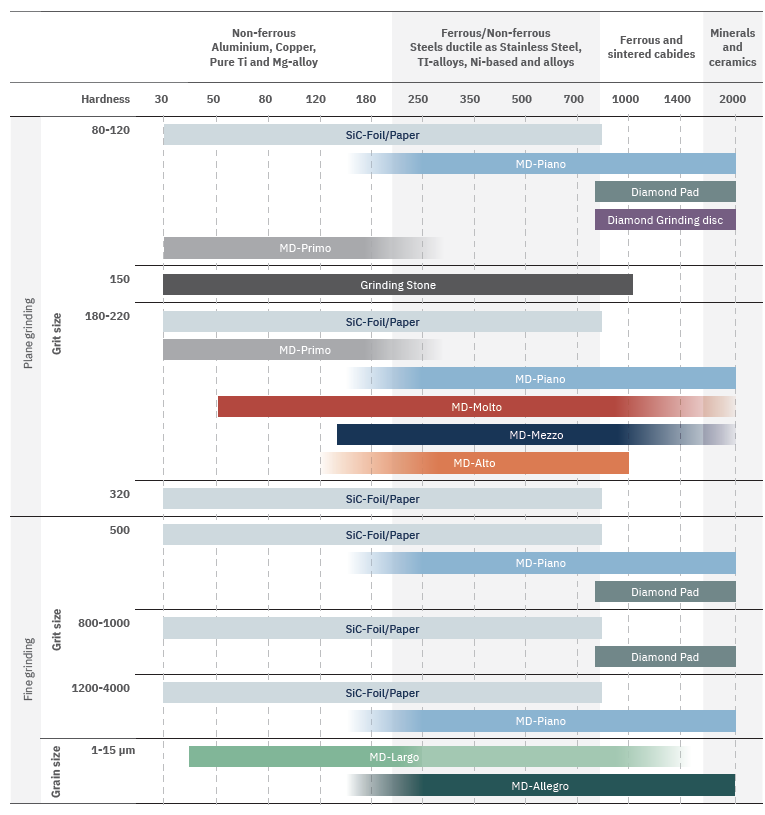

Mechanical preparation is the most common method for preparing metallographic specimens for microscopic examination. It involves using abrasives in progressively finer steps to remove material until the desired finish is achieved. This process can be divided into two main stages: grinding and polishing.

- Grinding: Removes material quickly and flattens the specimen surface using coarse to fine abrasives.

- Polishing: Refines the surface to remove scratches and imperfections, achieving a mirror-like finish for detailed microscopic analysis.

No matter your preparation goal—whether you need perfectly clear results or are willing to accept minor artifacts as long as they don't interfere with your analysis—our consumables can help you optimize your grinding and polishing process.

Grinding Consumables for Every Need

Whether you need a versatile grinding solution for occasional specimens or a high-performance consumable for high-volume labs, our full range of grinding consumables covers all requirements.

- Flexible Grinding Solutions: Ideal for occasional or varied specimen preparation, providing the adaptability needed in diverse lab environments.

- High-Performance Options: For labs that handle large volumes, these consumables deliver efficiency and consistency across every sample.

- Materials Covered: From hard, brittle materials to soft, ductile ones, our consumables are designed to maximize reproducibility and optimize quality, speed, and efficiency without over-processing.

Polishing Consumables for Any RequirementOur complete range of polishing consumables offers solutions for all types of materials, preparation goals, and lab setups. Whether you have a high-throughput demand or only polish specimens occasionally, we have you covered with a variety of formats, including:

- Diamond Polishing Suspensions: Available in multiple grades and concentrations for precise, high-quality polishing of any material.

- Versatile Options: Choose from a range of suspensions, pastes, and cloths that ensure consistent, reliable results, enhancing process speed, efficiency, and safety.

Maximize Your Process EfficiencyBy selecting the right grinding and polishing consumables, you can significantly improve your lab’s process efficiency, reduce preparation times, and ensure the highest quality outcomes. Our consumables are designed not only to meet the demands of diverse materials and applications but also to protect your equipment and extend its lifespan, providing a reliable and cost-effective solution for every lab setup.

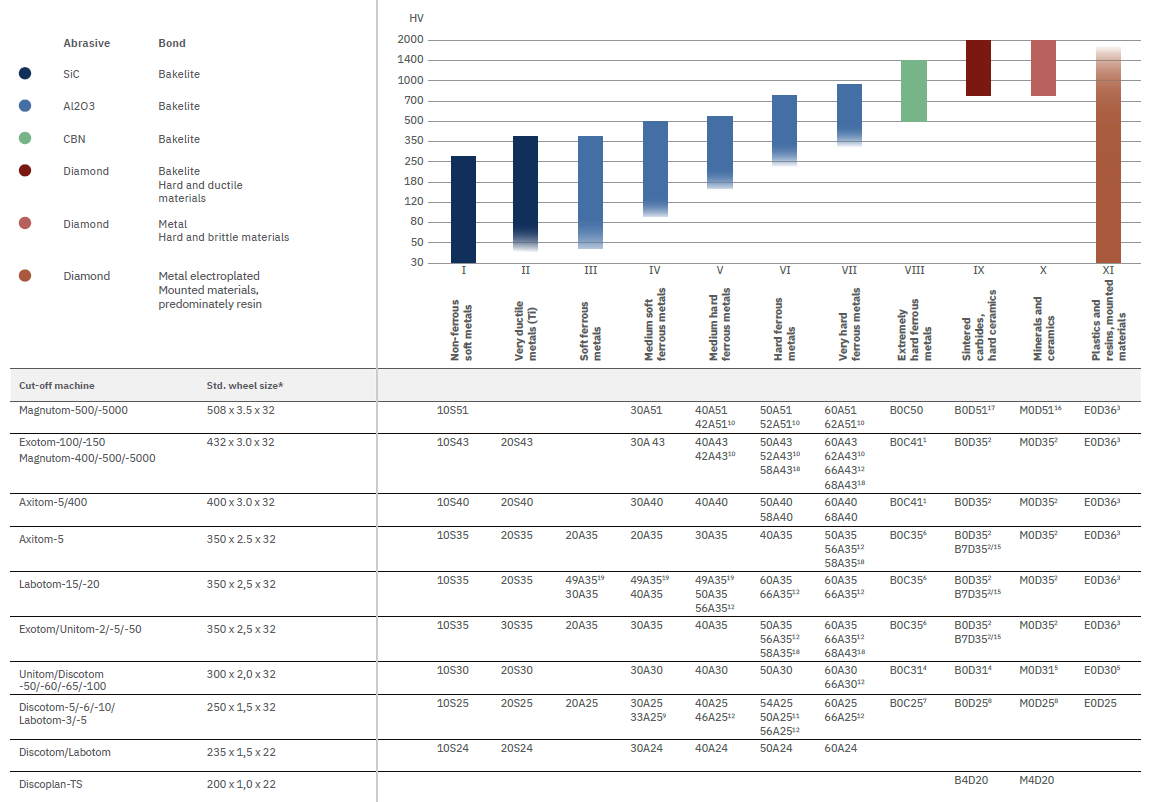

Cutting Consumables: Optimize Your Materialographic Preparation

Struers’ cutting consumables, including a comprehensive range of cut-off wheels and additives, are designed to deliver precise, high-quality sectioning of all material types without structural changes, overheating, or deformation. Our consumables are specifically engineered for Struers’ cutting machines, incorporating state-of-the-art abrasive wet cutting techniques to produce specimens in perfect condition for the next preparation step.By using Struers’ cutting consumables, such as our cut-off wheels paired with Cooli Additive and Cooli Additive Plus, you can achieve up to three times more cuts per wheel. This extends the life of your consumables and enhances cutting precision, reducing preparation time and costs.

Six Ways to Improve Speed, Efficiency, and Quality in Materialographic Cutting

Cutting is the foundation of a robust quality control process. Getting this step right improves specimen quality, speeds up the preparation process, and reduces the need for extensive grinding and polishing. Below, we explore six common cutting mistakes and provide expert tips on how to avoid them, ensuring your cutting process is fast, efficient, and precise.

1. Eliminate Burrs to Speed Up Your Preparation Process

Burrs are raised edges that form after sectioning and must be removed before analysis, adding time to your preparation. Avoid burrs by:

- Clamping on Both Sides: Proper clamping on both sides of the sample prevents burr formation as the material separates.

- Slowing Down Feed Speed: Use an automatic cut-off machine with controlled feed speed to maintain low speeds near the end of the cut, minimizing burrs.

2. Improve Sample Quality by Avoiding Thermal Damage

Thermal damage, characterized by surface burning and microstructural changes, results from incorrect sectioning and requires removal through extensive grinding and polishing. To prevent thermal damage:

- Select the Right Cut-off Wheel: Choosing the correct wheel for the material significantly reduces the risk of thermal damage and minimizes grinding time.

- Use an Automatic Cut-off Machine: Adjustable feed speeds in automatic machines help maintain the correct cutting pace, preventing overheating.

- Check Cooling Systems: Ensure adequate cooling during cutting by checking coolant levels and positioning the nozzle optimally over the cut section.

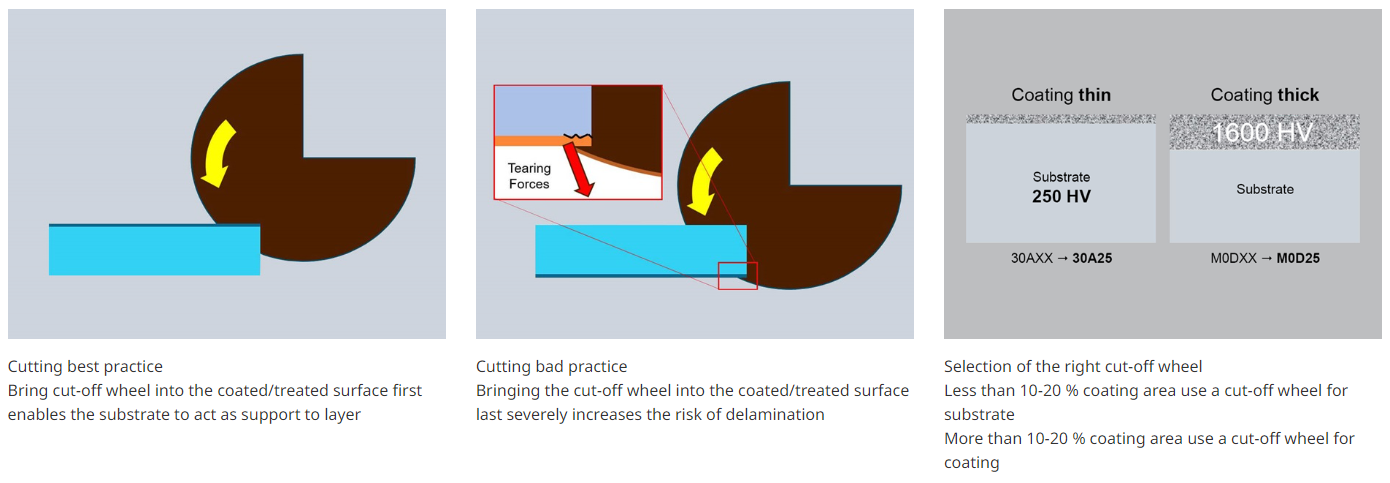

3. Improve Reproducibility by Avoiding Cracks in Brittle Materials or Coatings

Cracking is common in brittle samples or those with coatings and often necessitates a second cut. To reduce cracking:

- Adjust Cutting Technique: Cut into the coated side of the workpiece to use the base material as support.

- Support the Specimen: Use vacuum impregnation with epoxy resin to fill pores and cracks, providing full support during sectioning.

- Use an Automatic Cut-off Machine: Automatic machines with adjustable feed speeds reduce the likelihood of cracks, especially in brittle materials.

4. Protect Your Cut-off Wheel by Avoiding Pinching

Pinching occurs when internal stresses in hardened steel cause the workpiece to pinch the cut-off wheel, leading to wheel damage or deformation of the sample. Prevent pinching by:

- Using Pinch-Reduction Clamping Tools: These tools limit deformation during longitudinal cuts, protecting the wheel and ensuring the integrity of your sample.

5. Learn How to Clamp and Cut Irregular Shapes

Irregularly shaped workpieces can be challenging to secure, leading to movement during cutting and poor quality. Improve clamping by:

- Using Support Blocks: Support larger workpieces during sectioning to prevent overturning.

- Mounting in Resin: Smaller workpieces can be mounted in resin, like RepliFix, for easier clamping.

- Using Custom-Made Clamping Tools: Custom tools tailored to specific workpiece shapes can significantly improve clamping efficiency and cutting quality.

6. Don’t Cut the Work Surface

Accidentally cutting into the cutting table can occur when the cut-off wheel deflects. Avoid this mistake by:

- Using Lower Feed Speeds: Slower speeds reduce mechanical impact, stabilizing the wheel and preventing it from veering off course.

- Switching to a Softer Cut-off Wheel: A softer wheel is less likely to deflect into the table. Alternatively, reduce the RPM if changing the wheel is not an option.

Enhance Your Cutting Process with Struers

Struers offers a wide selection of cutting consumables tailored to optimize your materialographic preparation. From the right cut-off wheel to cooling additives and specialized clamping tools, our solutions ensure that each cut is precise, efficient, and tailored to your specific needs. Explore our comprehensive guides and equipment to find the perfect combination of consumables for your cutting tasks, ensuring high-quality specimens and faster analysis in every preparation stage.

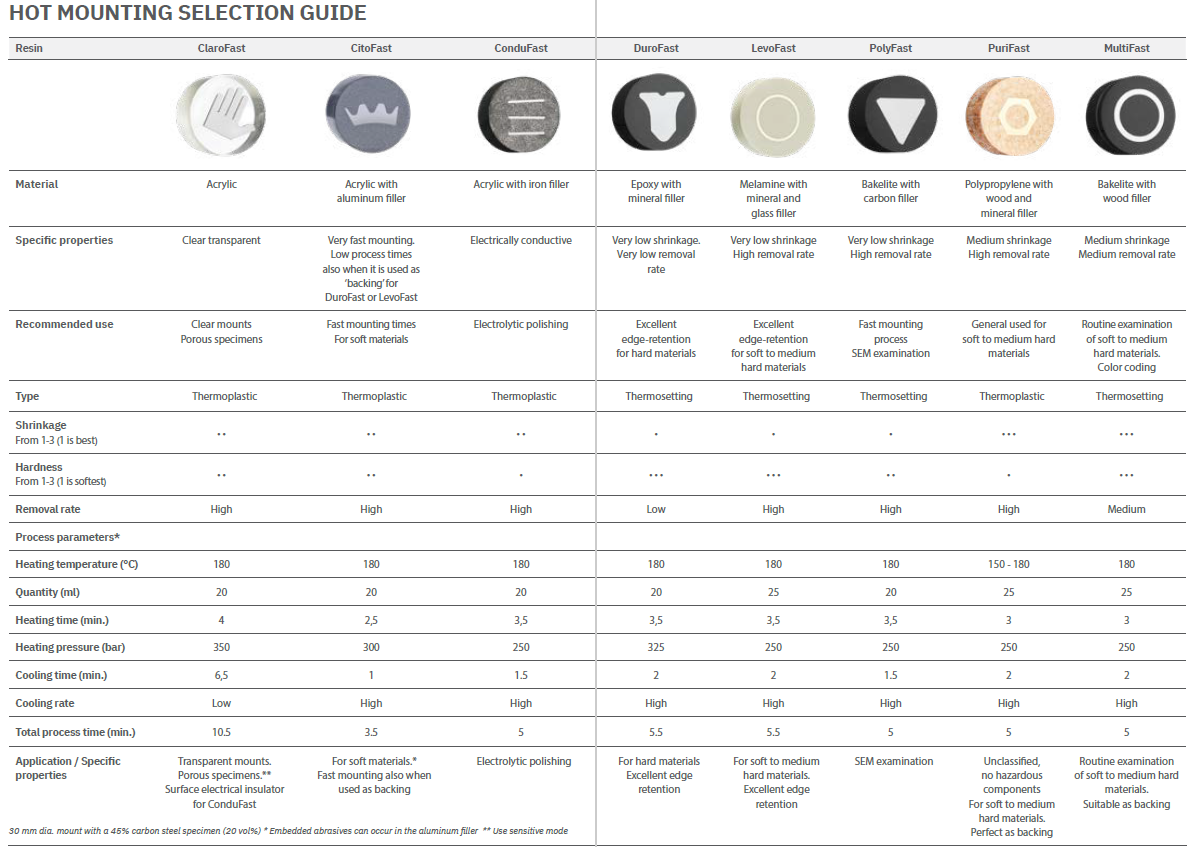

Hot and Cold Mounting Consumables: Tailored Solutions for Every Specimen

Mounting is an essential step in materialographic preparation, offering protection and ease of handling for fragile, small, or irregularly shaped specimens. Struers provides a comprehensive range of hot and cold mounting consumables, designed to meet the diverse needs of every lab setup.

Hot Mounting Consumables

Hot mounting involves using heat and pressure to embed specimens in resin, providing uniformity and excellent edge retention. Our hot mounting resins are available in various formulations to suit different specimen requirements:

- Thermoplastic Resins: Ideal for specimens that require a clear view, enabling easy examination and electrolytic polishing with or without conductivity.

- Thermosetting Epoxy and Melamine Resins: These resins contain high levels of mineral and glass fillers, offering enhanced support and edge retention.

- Conductive Bakelite Resin: Contains carbon filler, making it suitable for specimens that require conductivity. Available in various colors and tablet sizes to cater to specific mounting needs.

Our selection of hot mounting consumables ensures that each specimen is perfectly mounted, facilitating the next steps of preparation with high-quality, reproducible results.

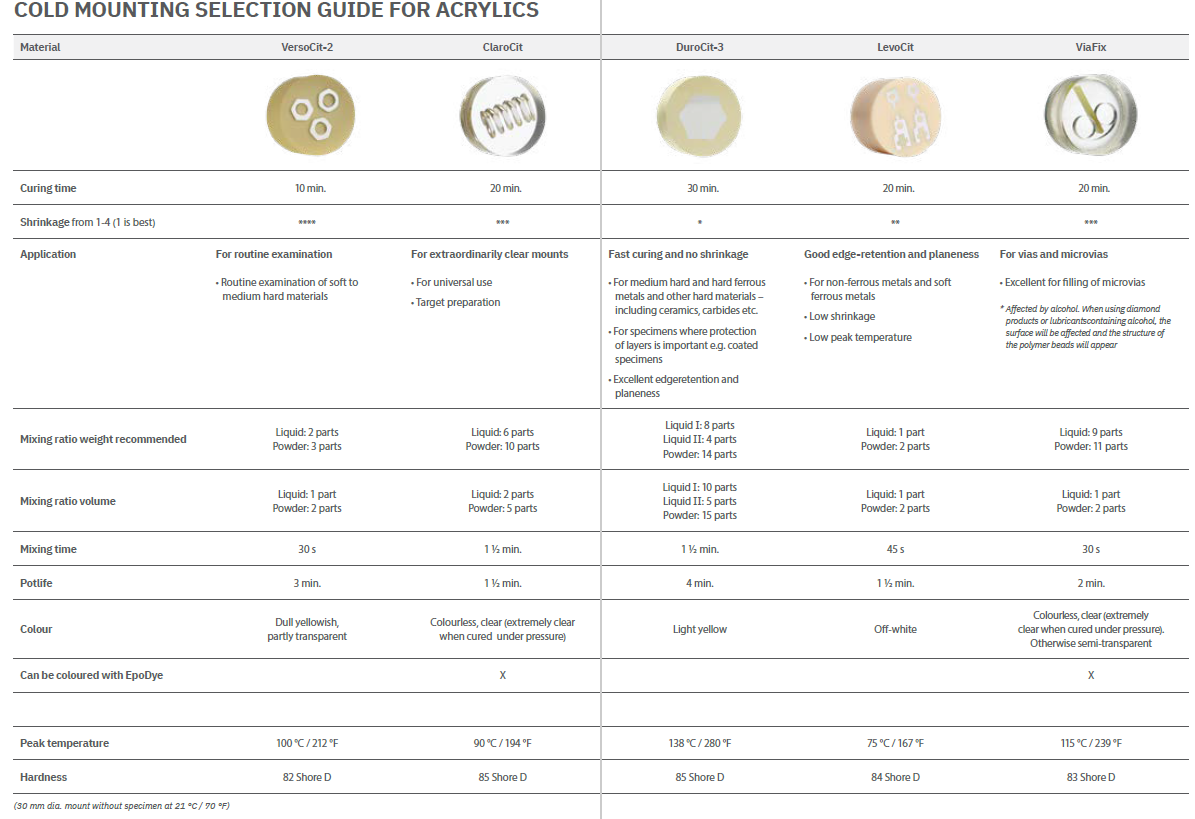

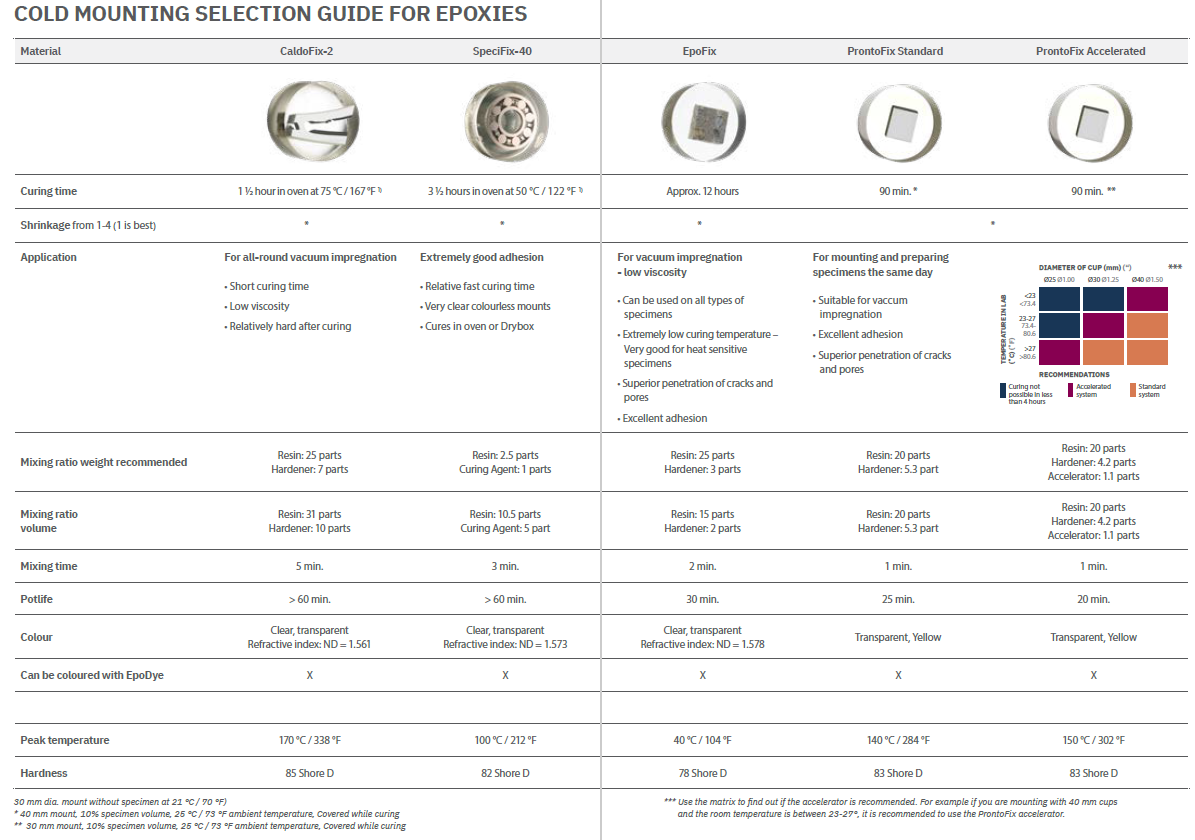

Cold Mounting Consumables

Cold mounting is a preferred method for specimens that are sensitive to heat or require special care during preparation. Our range of cold mounting consumables includes:

- Epoxy Resins: Known for their low shrinkage and excellent adhesion, epoxy resins are suitable for a wide range of applications, including mounting fragile or porous specimens.

- Acrylic Resins: Quick-curing and easy to use, acrylic resins offer a balance of performance and convenience, ideal for routine cold mounting tasks.

- Cold Mounting Consumable Kit: This kit includes 100 dispensing tubes and a protecting chamber, simplifying maintenance of the vacuum chamber and ensuring efficient, high-quality mounting.

Both hot and cold mounting consumables are carefully designed to provide optimal results for different specimen types, ensuring that each preparation step is as effective and efficient as possible. Explore our full range of mounting solutions to find the perfect consumables for your lab’s specific requirements.