Hardness Testing

Hardness Testing: An Essential Tool for Quality Control and R&D

Hardness testing is a fundamental part of many quality control procedures and R&D activities. It provides insight into a material’s properties, such as strength, ductility, and wear resistance, helping determine whether a material or treatment is suitable for specific applications.

What is Hardness Testing?

Hardness testing measures a material’s resistance to permanent deformation by penetration. It involves pressing an indenter into the material’s surface and measuring the resulting depth or size of the impression. Hardness itself is not a fundamental property but must be evaluated with regard to several factors: the load applied, the loading duration, and the indenter geometry.

Common Hardness Testing Methods

- Rockwell Hardness Test (HR)

- Measures the depth of an indent under a given load.

- Fast and suitable for production control of larger metallic samples.

- Commonly used for advanced tests like the Jominy end-quench test (HRC).

- Vickers Hardness Test (HV)

- Utilizes a diamond pyramid indenter to create an impression, measured optically.

- Suitable for all solid materials and a wide range of applications, including microhardness testing and testing welds.

- Knoop Hardness Test (HK)

- Similar to Vickers but uses an asymmetrical pyramidal diamond indenter.

- Ideal for brittle materials like ceramics and thin coatings.

- Brinell Hardness Test (HBW)

- Uses a tungsten carbide ball to leave a large indentation, read optically.

- Best suited for large samples and materials with coarse or inhomogeneous grain structures, such as castings and forgings.

How to Select the Best Hardness Test Method

When selecting a hardness testing method, consider the material’s microstructure, size, condition, and the required accuracy. The choice of test depends on factors such as the homogeneity of the material, required compliance with standards, and whether mounting is necessary.

Ensuring Accuracy and Repeatability in Hardness Testing

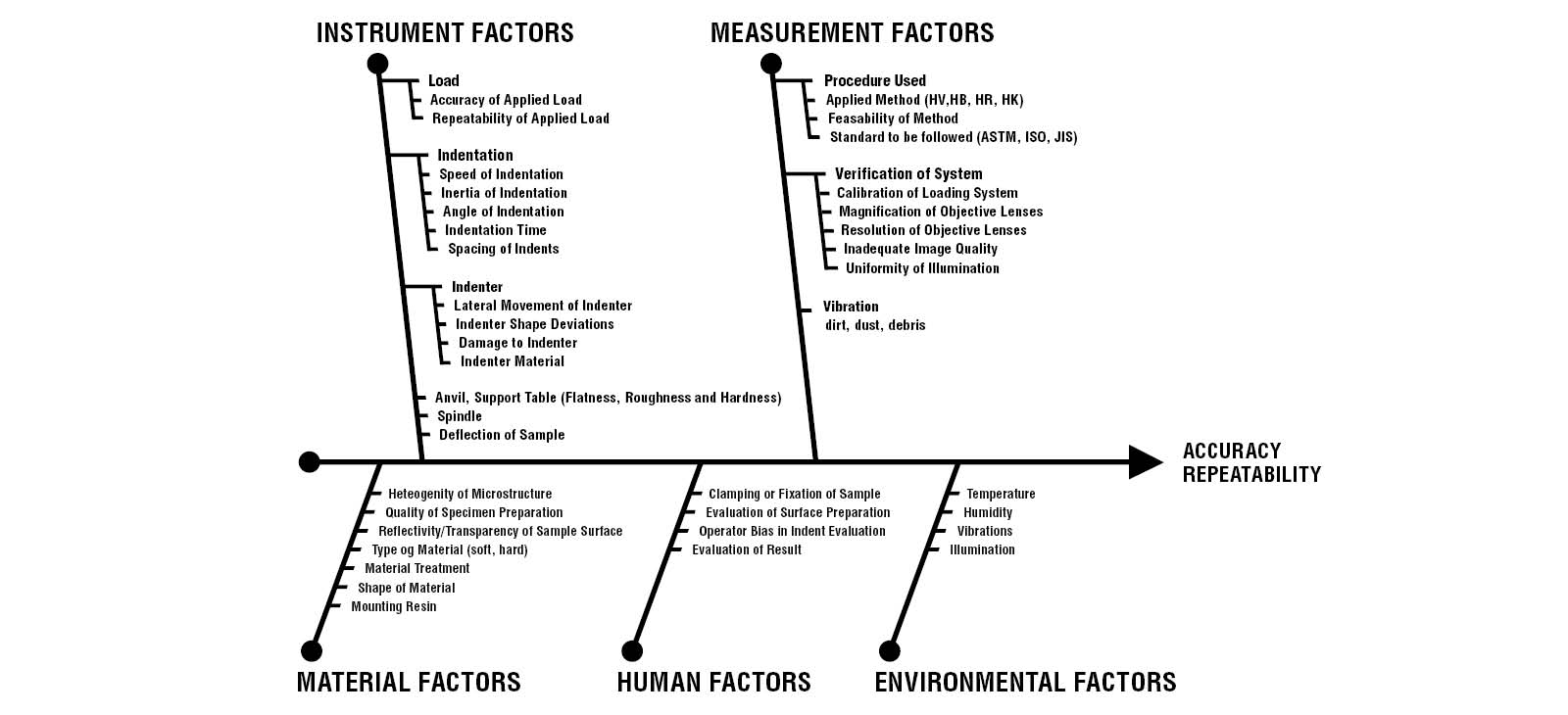

Several factors influence the accuracy of hardness tests:

- External conditions: Control light, dirt, vibrations, temperature, and humidity.

- Equipment setup: Secure the tester and ensure the indenter is perpendicular to the surface.

- Surface preparation: Proper preparation is crucial, especially for microhardness tests. Deformations from cutting and grinding must be removed to avoid affecting results. For loads under 300 gf, oxide or electrolytic polishing is recommended to achieve a deformation-free surface.

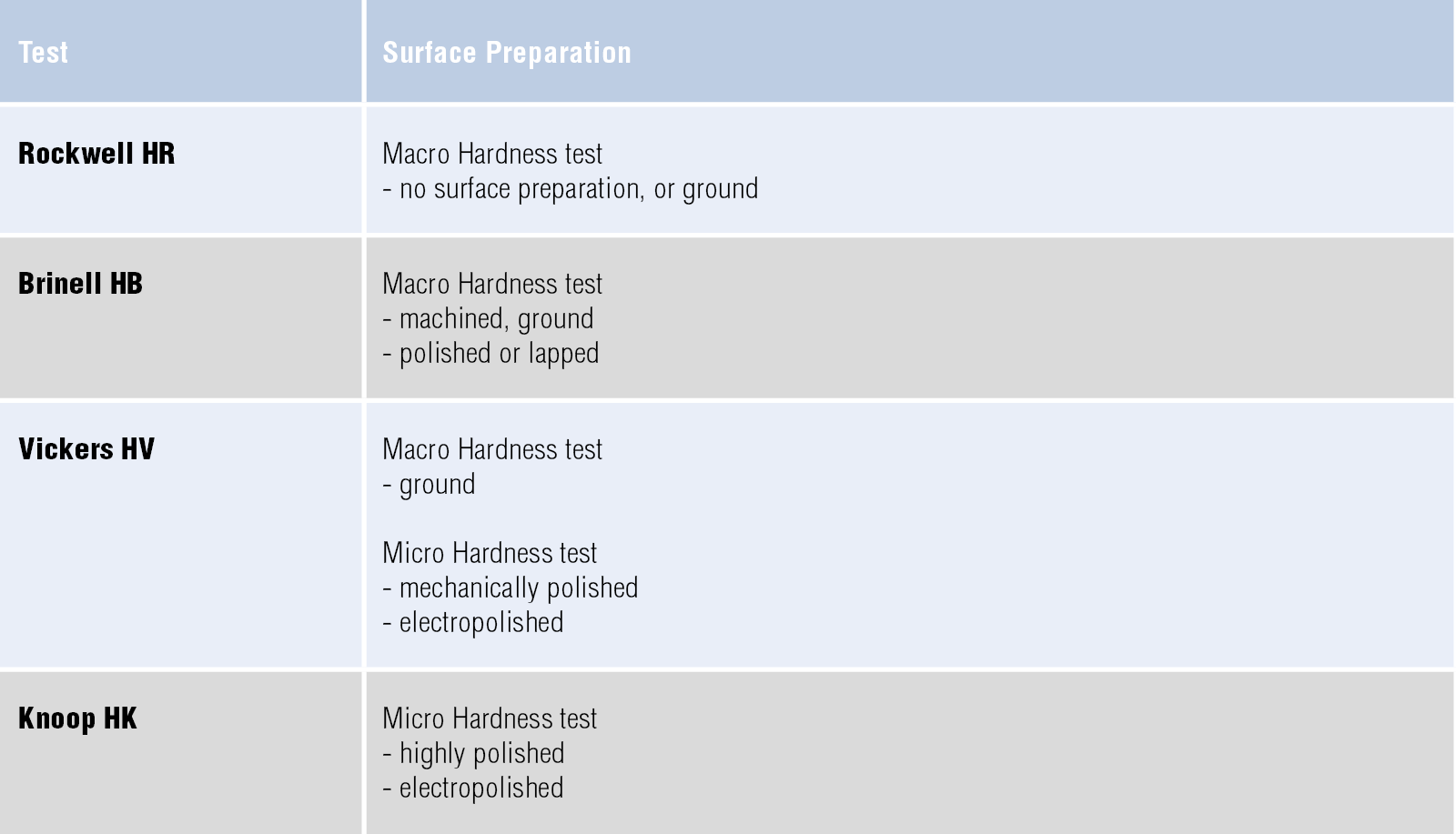

Surface Preparation Requirements

- Macro hardness testing: A ground surface is often sufficient.

- Micro hardness testing: Requires polished or electropolished surfaces to clearly see indentations.

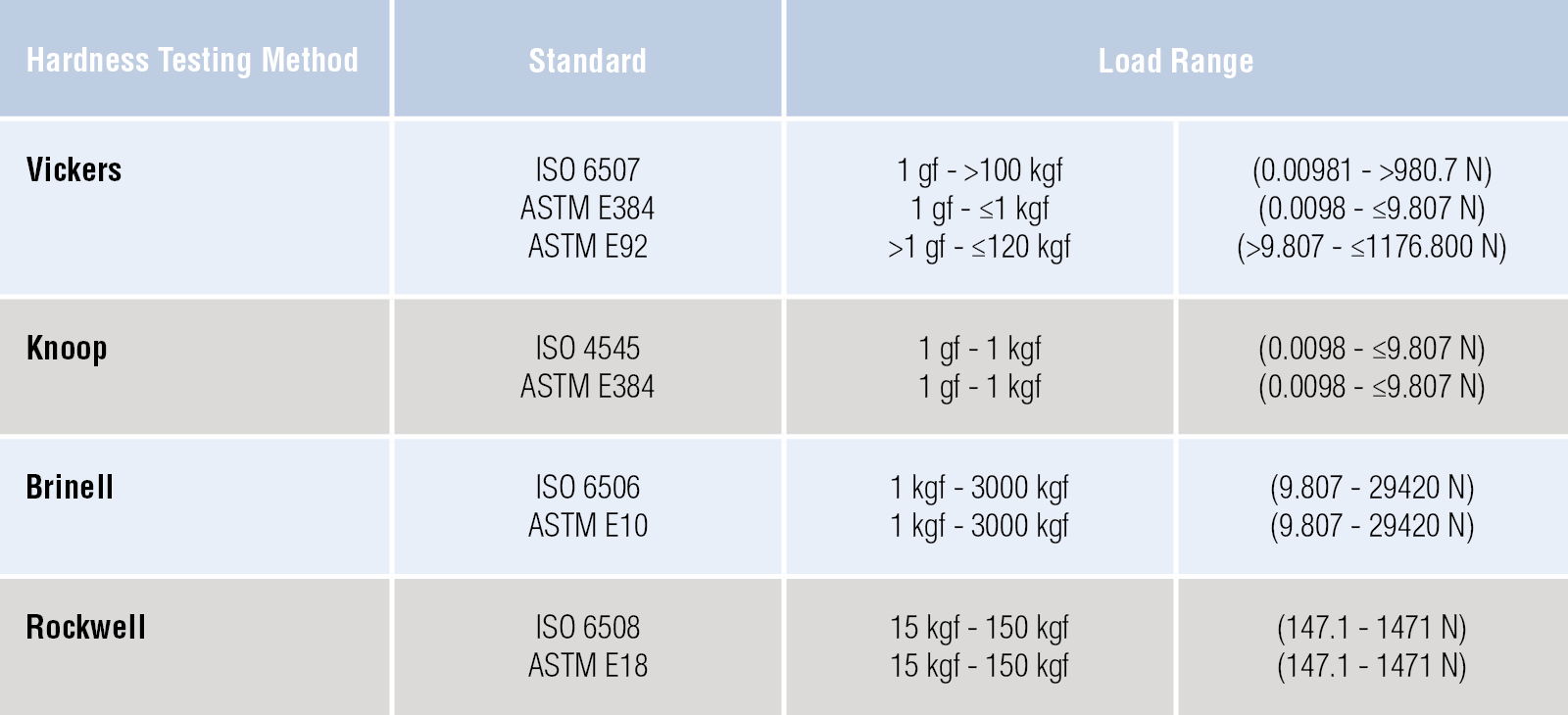

Defining Hardness Testing Loads

Hardness testing loads range from micro (≤ 1 kgf) to macro (> 1 kgf). The load affects the indentation size, which should be optimized for the highest possible accuracy.

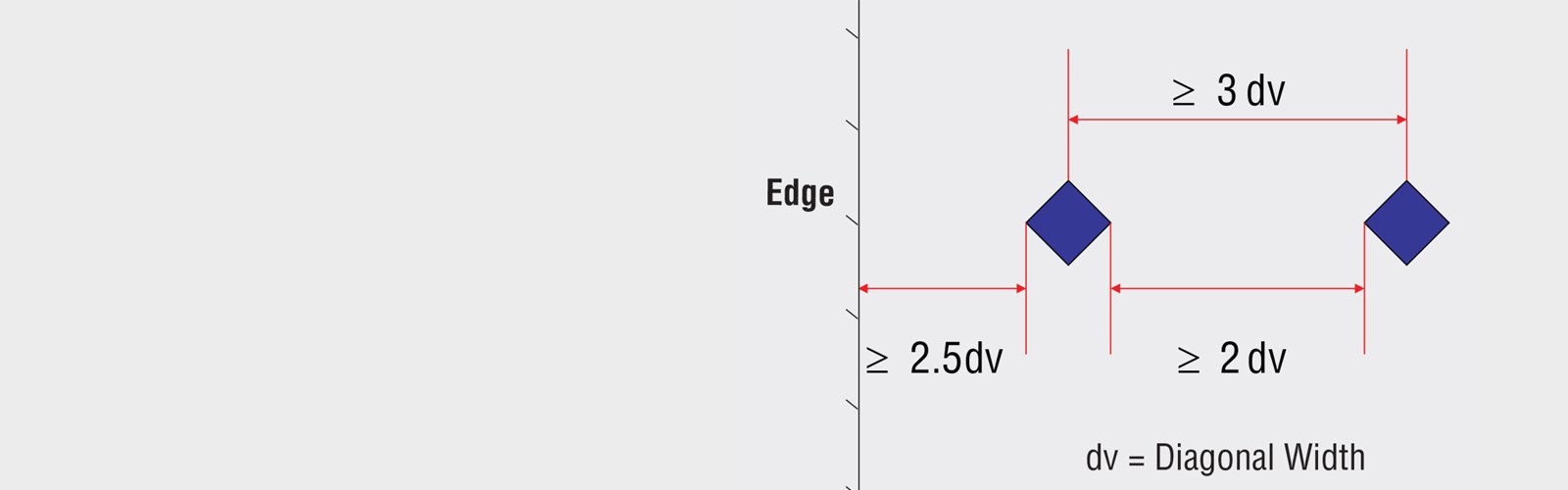

Indentation Spacing

To avoid overlapping deformation effects, standards specify minimum spacing between indents. For example:

- Steel, copper, and copper alloys: At least three diagonal widths between indents.

- Lead, zinc, aluminum, and tin: At least six diagonal widths.

Comprehensive Hardness Testing Solutions

We offer a broad range of hardness testers and accessories to ensure optimal reproducibility, precision, and productivity for every testing scenario. Whether you need manual, semi-automatic, or fully automatic solutions, our selection is designed to meet the diverse needs of laboratories, research facilities, and production environments.

Types of Hardness Testing Equipment

- Manual, Semi-Automatic, and Automatic Hardness Testers

- Ideal for applications ranging from occasional laboratory tests to high-volume production settings.

- Choose the level of automation based on your requirements for speed, precision, and workflow control.

- Dedicated Hardness Testers for Specific Methods

- Vickers Hardness Testers: For precise testing of all solid materials with optical measurement of indentations.

- Knoop Hardness Testers: Designed for brittle materials and thin layers, such as coatings, with an asymmetrical diamond indenter.

- Brinell Hardness Testers: Suitable for large samples and materials with coarse structures, using a ball indenter.

- Rockwell Hardness Testers: Fast and direct measurement of indentation depth, ideal for production control of metallic materials.

- Universal Hardness Testers

- Capable of performing multiple hardness testing methods in a single machine, providing flexibility and efficiency in diverse testing environments.

Hardness Testing Equipment Range

- Portable Bench-Top Machines: Ideal for occasional testing and smaller samples.

- Heavy-Duty Floor Solutions: Designed for testing large samples and handling high volumes, perfect for industrial and R&D settings.

Essential Accessories for Hardness Testing

For reliable and reproducible results, choosing the right accessories is crucial. Our comprehensive range includes:

- Specimen Holders: Ensure proper positioning and stability of the sample during testing.

- Clamps, Vices, Jaws, and Anvils: Secure the sample, maintaining precision and accuracy in the test results.

- Indenter Types: Includes carbide and steel balls, pyramidal diamonds, and other specialized indenters for Vickers, Knoop, Brinell, and Rockwell tests.

- Objective Lenses: High-quality lenses for optical measurement in Vickers, Knoop, and Brinell testing, enhancing accuracy in readings.

- Test Blocks: Calibrated blocks for verifying the accuracy and repeatability of hardness tests.

- Spring Levers, Gauges, and Nose Cones: Essential components to maintain precise control and measurement during testing.

Software Solutions for Hardness Testing

Our advanced software simplifies complex testing requirements, enhancing the accuracy and efficiency of hardness tests across various industries. Key features include:

- Predesigned Preferred Applications: Streamlined for common testing workflows, reducing setup time.

- Advanced Workflow Control: Enables customization and automation of testing procedures, ensuring consistency and efficiency.

- Enhanced Reporting: Comprehensive data analysis and reporting tools that simplify the documentation of test results.