Imaging Solutions

Automated Image Analysis in Materialography

Automated image analysis in materialography refers to the digital and quantitative evaluation of microstructural images. It plays a crucial role in examining material characteristics, such as grain size, inclusions, layers, and phases, by providing precise quantitative measurements like length, width, and area. The digitization of these images facilitates the handling of large data volumes, which is essential for ensuring a robust statistical analysis.

Software Automation in Image Analysis

Automating image analysis with software eliminates the labor-intensive manual processes of identification, counting, and comparison. Software solutions can be broadly categorized into:

- Advanced Universal Software:

Used by experts, this software is versatile and can handle a wide range of complex analyses. - Simpler, Dedicated Software:

Optimized for specific or standardized analyses, these solutions are user-friendly and require less technical expertise.

Steps in Automated Image Analysis

The process of automated image analysis for measuring microstructural features involves six key steps:

- Specimen Selection

- Choose a representative specimen that includes all the relevant microstructural information needed for analysis.

- Specimen Preparation

- Prepare an artifact-free surface to prevent interference with the automated image analysis.

- Image Illumination and Filtration

- Enhance image contrast and ensure optimal focus by adjusting the lighting and applying appropriate filters.

- Image Digitization

- Convert the analog live image into a digital format to enable further processing and analysis.

- Image Processing

- Use software filters to remove noise, enhance contrast, and highlight key features for more precise analysis.

- Image Measurement and Results

- Perform quantitative measurements, calculations, and generate results from the processed image data.

Materialographic Analysis Solutions

Our materialographic analysis equipment is designed to deliver faster, simpler, and more accurate results compared to conventional microscopy methods. The advanced imaging tools provide high precision in weld testing, structure verification, and grain size measurement. Key features include:

- Simple Operation: Easy-to-use systems that minimize training requirements.

- Fast and Efficient: Rapid analysis, significantly reducing turnaround time.

- High Precision: Accurate measurements that ensure reliable data output.

Equipment for Materialographic Analysis

To support efficient materialographic analysis, we offer a variety of equipment and tools, including:

- Dedicated Software: Optimized for specific materialographic tasks to streamline the analysis process.

- Portable Microscopes: Compact and versatile microscopes ideal for fieldwork and laboratory environments.

- Material Replication Systems: Capture and analyze surface details accurately without sample damage.

- Imaging Tools: Specialized for weld bead inspection, structure verification, and grain size measurement.

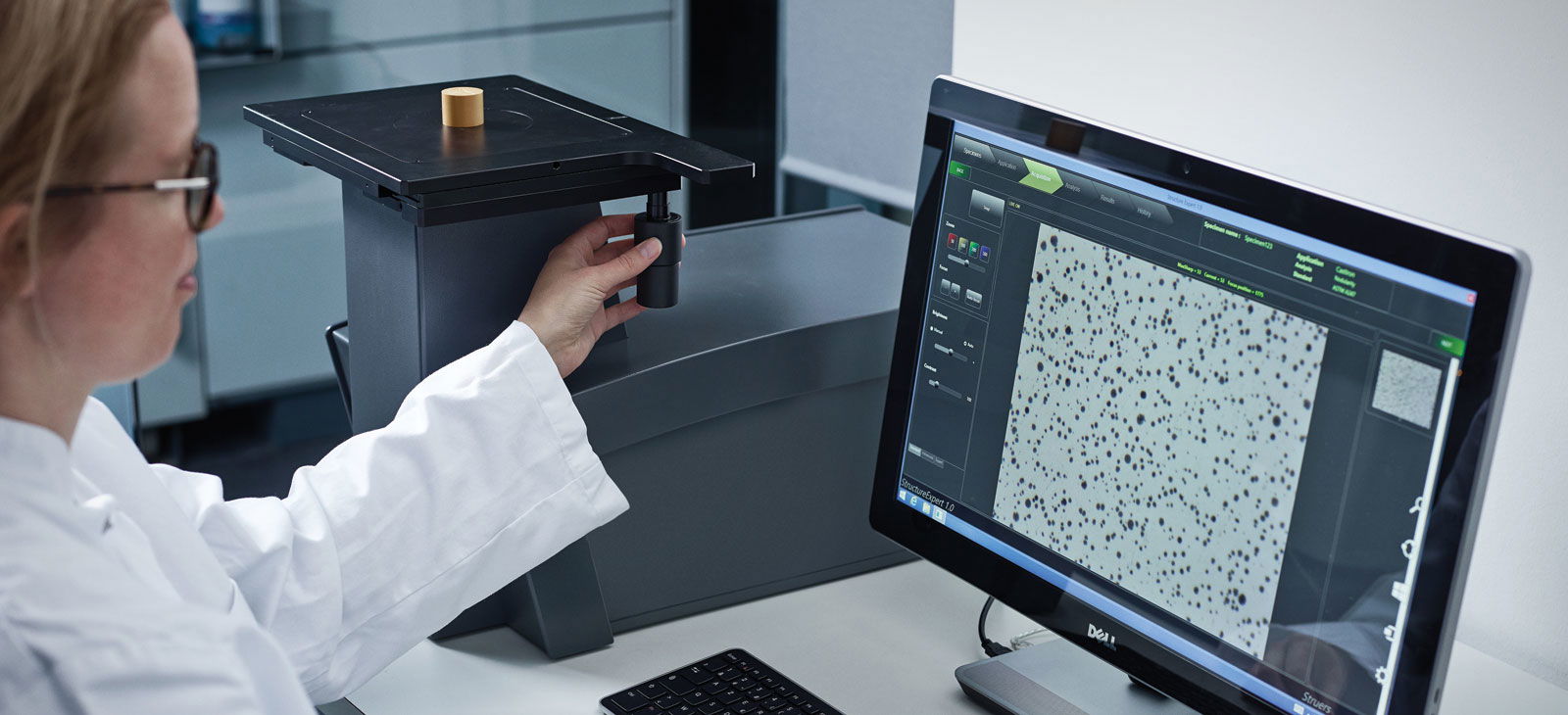

StructureExpert – The Ultimate Solution

For a comprehensive materialographic analysis solution, StructureExpert provides an all-in-one system that verifies structures and delivers accurate data in just 30 seconds. It includes:

- StructureExpert: A versatile tool for general structure verification.

- StructureExpert Weld: Specially designed for weld inspection and analysis.

- Replication System: For precise material surface replication and measurement.

Materialographic Analysis Equipment and Products

Materialographic analysis requires precise and reliable equipment designed to meet the needs of both laboratory and production environments. Here's an overview of the specialized equipment and products available:

1. StructureExpert

- Features:

- Auto-Illumination and Auto-Focus: Optimizes image capture by adjusting lighting and focus automatically for clear, high-quality images.

- Dedicated Software: Tailored for specific applications, enhancing the ease of use and efficiency.

- Versatile Application: Suitable for both production and lab environments, providing an all-in-one solution for structural verification and data analysis.

2. Replication System (RepliSet, RepliFix, Transcopy)

- Features:

- Highly Accurate: Captures fine details of material surfaces with high fidelity.

- Non-Destructive: Allows for surface replication without altering or damaging the original specimen.

- Flexible: Adapts to various material types and surface conditions.

- Complete System: Includes replica foils and accessories designed for precise replication of structures for further analysis.

3. StructureExpert Weld

- Features:

- Unique Inverted Optical System: Allows for efficient examination of weld beads with minimal setup.

- Dedicated Software: Streamlines weld analysis, offering advanced process management tools.

- Efficient and Accurate: The only stand-alone imaging tool specifically designed for weld bead control, enhancing accuracy and consistency in weld inspections.

4. PSM10 Portable Field Microscope

- Features:

- High-Resolution Camera with Sony Sensor: Ensures high-quality images with superior detail.

- 10-Inch Touchscreen Tablet: Large display for easy viewing and operation, enhancing user experience.

- Large Live Image: Simplifies focusing, making it ideal for professionals who need precision and ease of use in the field.

- CMOS Sensor, 3 Megapixels: Provides high-resolution digital images tailored to the demands of materialographic analysis.