Liquid Penetrant Testing System

Advanced Penetrant Testing Systems: Ensuring Quality and Compliance

Penetrant testing (PT) is a crucial non-destructive testing method used to detect surface defects in a wide variety of materials. The demands on testing stations and systems are multifaceted, requiring adherence to industry standards, customer specifications, and legal requirements related to occupational health and safety. Our expertise in non-destructive material testing ensures that we meet these challenges effectively.

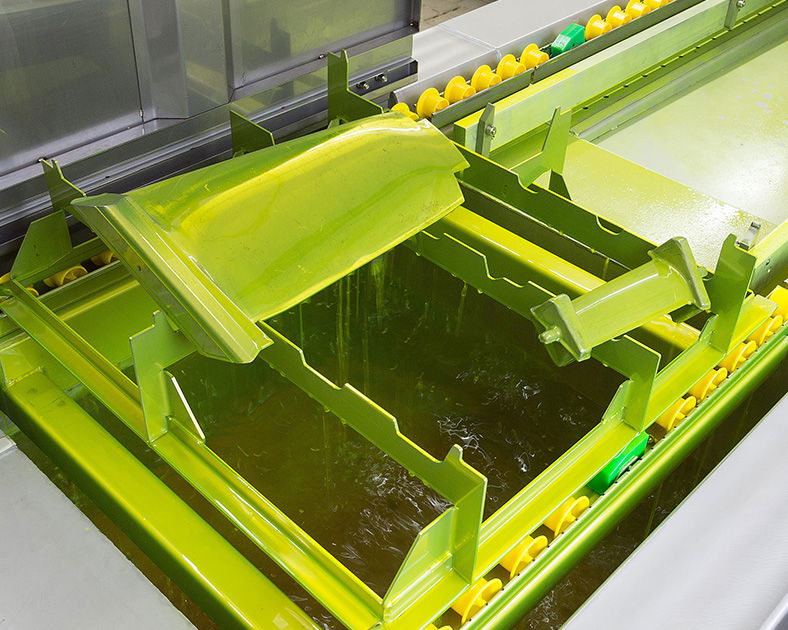

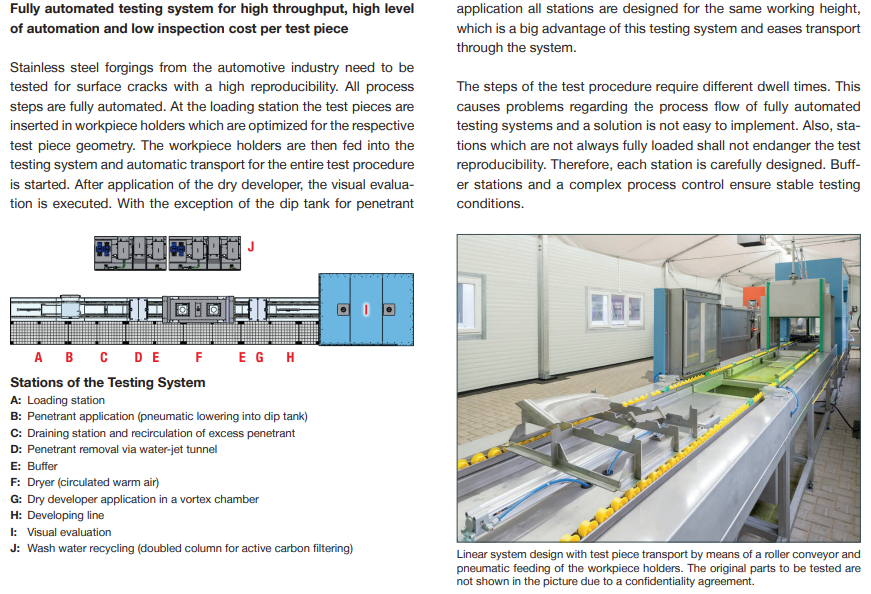

Fully Automatic Systems for Penetrant Testing

Fully automatic penetrant testing systems are engineered for high throughput and reproducibility. By automating key process steps, these systems significantly reduce human error and variability, making them ideal for large-scale production environments.

Key Features:

- Automated Process Steps: Each stage of the testing process, from penetrant application to washing and drying, is fully automated, ensuring consistency and reliability.

- High Throughput: Designed for large series with identical components, these systems can handle a significant volume of test parts efficiently.

- Compliance and Safety: Fully automated systems adhere to stringent industry standards and regulations, ensuring safety in handling hazardous materials.

Semi-Automatic Testing Stations for Penetrant Testing

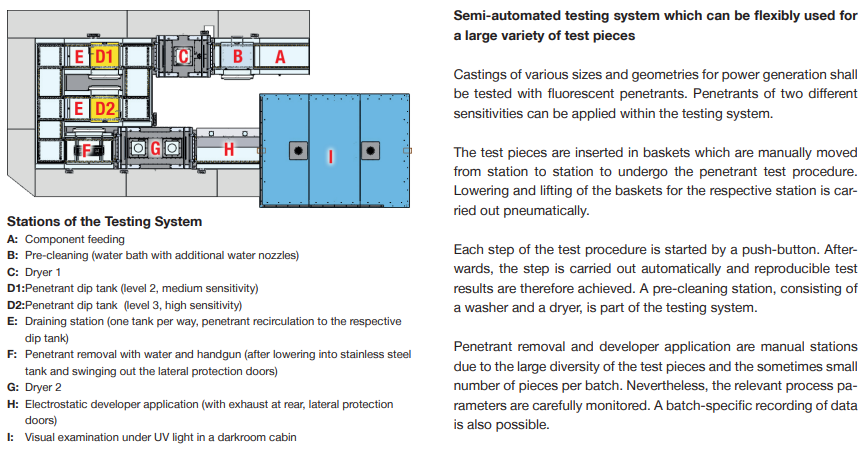

For smaller series or situations requiring flexibility, semi-automatic penetrant testing systems offer a practical solution. While many processes are automated, operators still engage in critical steps, allowing for adaptability based on varying component sizes and specifications.

Key Features:

- Increased Throughput: Semi-automatic systems enable a higher inspection rate, making them optimal for small series production.

- Efficient Design: Equipped with lifting systems for baskets or heavy components and roller rails for easy transport, these systems streamline the inspection process.

- Automated Washing and Drying: To enhance efficiency, the washing and drying processes are automated, ensuring quick turnaround times.

- Standard-Compliant Illumination: Adequate lighting is crucial for effective inspection, and these systems are designed to meet standard compliance in illumination.