Spot Weld Ultrasonic Testing System

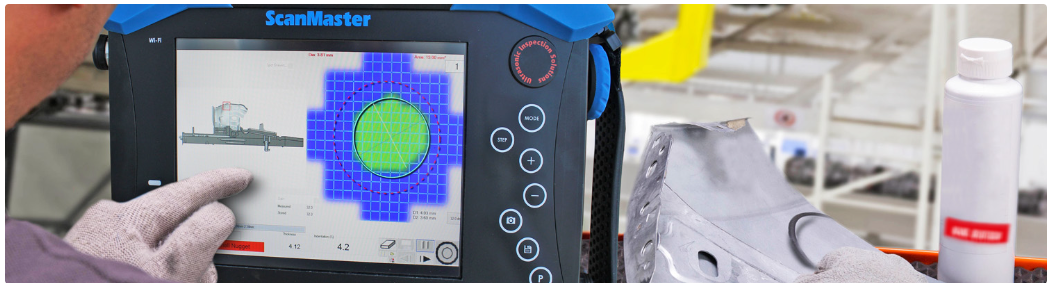

ScanMaster Spot Weld Inspection Systems: Advanced Ultrasonic Testing Solutions

Overview

The ScanMaster series of spot weld inspection systems—UT/X, UT/MATE, and UT/PRO—utilize decades of proven algorithms to evaluate ultrasonic signals during the inspection of resistance-welded spot joints. Unlike destructive testing methods such as tear tests or hammer and chisel techniques, these systems maintain the integrity of the test parts. This not only reduces scrap but also allows for rapid inspection of multiple points in significantly shorter timeframes. The systems offer automatic evaluation, archiving, and statistical analysis for quick feedback on welding processes.

UT/X: Enhanced Ultrasonic Testing with Phased Array Technology

The UT/X represents a significant advancement over conventional systems. Key features include:

- Direct Measurement Capabilities: The UT/X system can directly measure the diameter of the weld lens, the welded area, and the residual wall thickness of the lens. This provides comprehensive insights into the quality of the weld.

- Matrix Element Arrangement: The arrangement of elements in a matrix allows for a complete inspection of weld spots up to 9 mm in diameter with a single probe. This efficient design enhances inspection accuracy and speed.

- Flexible Probe Options: The phased array probe can be utilized with both flexible water delay paths and rigid fixed delay paths, enabling adaptation to various weld spot geometries.

- Integration of Conventional Probes: In instances where the PA probe size may be a constraint due to component geometry, conventional probes can be integrated into the inspection plan, utilizing traditional evaluation algorithms.

Key Features of the ScanMaster Series

- Automatic Go/No-Go Decision Making: The system provides automatic classifications of spot weld quality, ensuring quick and reliable assessments.

- Extensive Test Setup Storage: Users can store virtually unlimited test setups, C-scans, and A-scans, facilitating streamlined operations and easy access to historical data.

- Comprehensive Evaluation Algorithms: The system employs well-established evaluation algorithms, supporting a range of applications from basic inspections to complex analyses.

- Support for Multi-Plate Combinations: The systems accommodate various combinations of 2, 3, and 4 plates, enhancing their versatility in different welding scenarios.

- Data Management and Reporting: With features such as SpotWeld Connect for data exchange and UltraSPIS for external data management, generating comprehensive test reports has never been easier.

Comments