Universal Materials Testing System - Servohydraulic

Instron’s Industrial Series consists of hydraulic-driven universal testing systems designed to provide large testing spaces, exceptional frame stiffness, and the robust durability required for testing high-strength materials. These systems are capable of handling forces of up to 2000 kN, making them ideal for demanding applications in industries such as aerospace, automotive, and construction.

Instron's Industrial Series (IPG Static Range) is composed of the DX, HDX and KPX series. Leveraging the proven two-space design, the DX and HDX systems are engineered for tension, compression, bend/flex, and shear testing. This design allows users to perform tension tests without needing to remove application-specific fixtures from the compression test space, streamlining the testing process and improving efficiency.

The KPX Models are designed for high-capacity tension, compression, bend/flex, and shear testing, featuring an ultra-large single test space and adjustable crosshead options. Prioritizing operator safety, these frames are built with high-quality materials, components, and expert craftsmanship. They are ideal for testing a wide range of materials, including metals, wire, concrete, fasteners, wood, and composites.

Both Models are fully integrated with Instron's advanced controller featuring a data acquisition rate of 1000 Hz synchronized over all measurement channels. Giving you the technological advancement of the electromechanical system and the rigidity of the hydraulic power. Instron IPG range uses a strain gauged loadcell rather than the old pressure gauge which correlates pressure to loads. The table below summarizes the difference between the different Load Cells:

| Feature | Static Load Cell | Pressure Gauge Load Cell | Piezoelectric Load Cell |

|---|---|---|---|

| Measurement Principle | Measures force or load directly via strain gauge technology. | Measures pressure, which is converted to force or load. | Measures dynamic loads through the generation of electrical charge under stress. |

| Application | Used primarily in testing machines for static loads (tension, compression). Instron patented its use by using the dynacell (integrating an accelerometer with it to eliminate the inertial forces making it perform accurately in dynamic performance) | Measures fluid pressure in hydraulic systems, which can be related to load. | Ideal for measuring dynamic loads, vibrations, and transient forces. |

| Accuracy | High accuracy, ideal for precision load measurements. | Less accurate due to indirect measurement of load through pressure. Any change in the hydraulic circuit would result in invalidating the calibration (even changing filters and oil seals). | Highly accurate in measuring dynamic loads, but not suitable for static loads. |

| Response to Dynamic Loads | Generally not suitable for rapidly changing loads. Except when integrated with an accelerometer. | Can handle dynamic conditions where pressure changes frequently. However, lower service life time. | Excellent response to dynamic or transient loads, poor with static loads. |

| Output | Produces a linear, direct load output. | Produces pressure readings, which must be converted to load. | Produces an electrical charge proportional to the applied dynamic force. |

| Cost | Typically more expensive due to higher precision and complexity. | More cost-effective for general pressure measurements. | Typically expensive due to sensitivity and specialized use in dynamic applications. |

| Calibration | Calibrated for specific force values directly. | Calibration depends on pressure-to-load relationship, which changes with time, making it not the best option when it comes to precision testing. | Requires careful calibration for dynamic force measurements. |

| Usage Environment | Common in material testing and laboratory environments. | Used in hydraulic systems and industrial equipment. | Ideal for environments requiring high-frequency force measurement, such as impact testing or vibration monitoring. |

| Durability | Durable for repeated static testing. | Built for rugged environments but may degrade in precision over time. | Highly durable for dynamic applications, but poor long-term stability in static conditions. |

| Maintenance | Requires regular calibration to maintain precision. | Less maintenance needed, but recalibration may be required for accurate load conversion. | Minimal maintenance, but can require specialized calibration for dynamic performance. |

| Sensitivity to Environmental Factors | Relatively stable under temperature and environmental variations. | Can be sensitive to fluid pressure changes due to temperature. | Highly sensitive to dynamic changes but affected by environmental factors like humidity and temperature. |

The DX Series

The DX Models are designed for high-capacity tension, compression, bend/flex, and shear testing, featuring a dual test space and a compact single footprint. Built with operator safety in mind, these frames incorporate high-quality materials, components, and craftsmanship, making them ideal for testing metals, wire rod, fasteners, concrete, and wood.

Features and Benefits

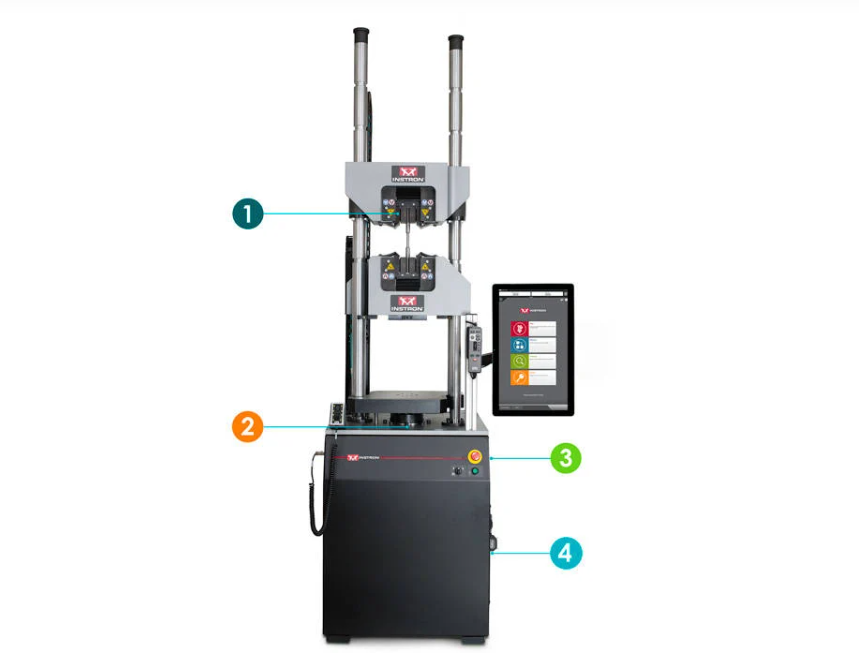

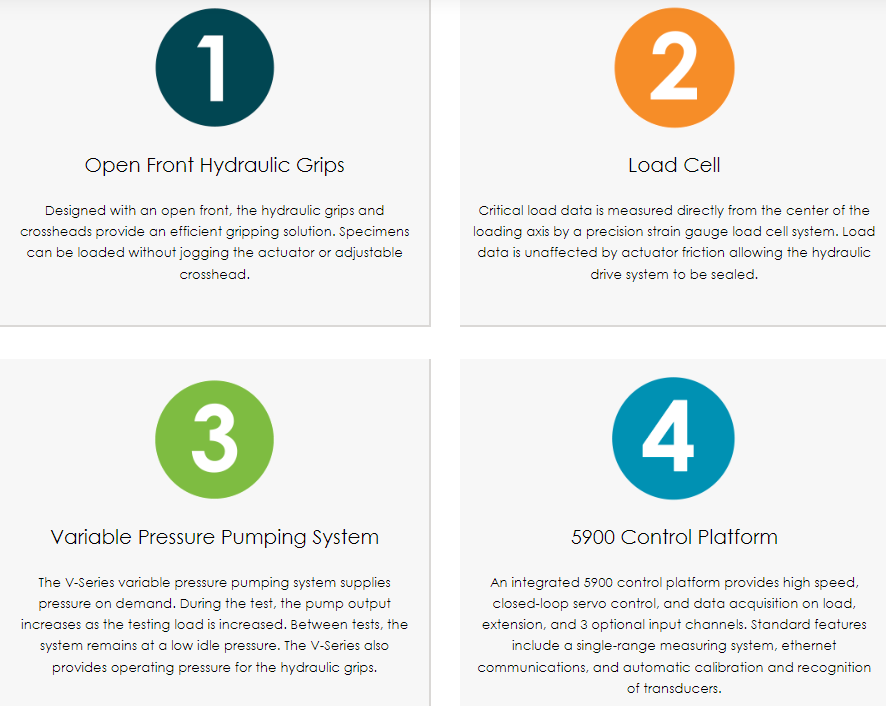

- Single footprint: Saves valuable floor space by combining the load frame, hydraulic power supply, and controller in one integrated package.

- Open-front grip design: Enhances operator safety and efficiency, allowing a limited number of jaw faces to cover a wide range of specimen sizes.

- Dual test space design: Improves safety and efficiency by allowing users to switch between tension and compression testing without the need to remove heavy fixtures.

- Ergonomic working height and controls: Increases operator comfort and productivity during testing operations.

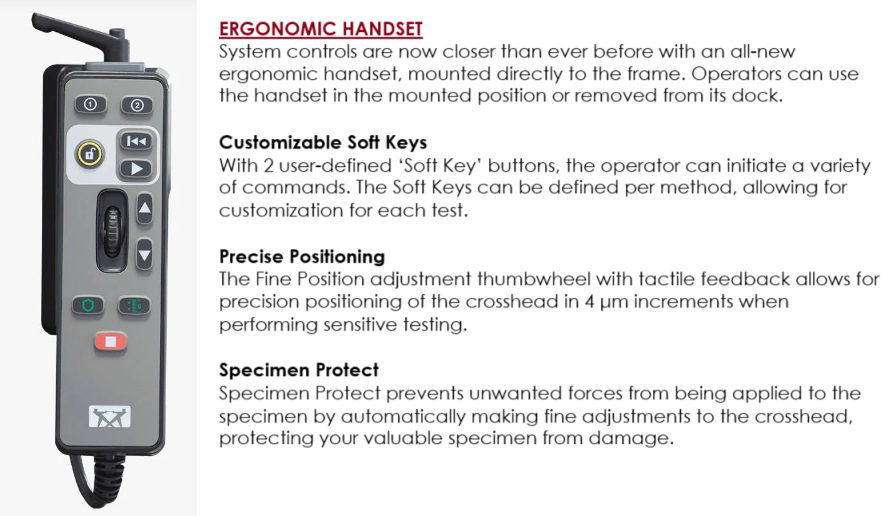

- Ergonomic handset: Features fine position adjustment, two programmable softkeys, start, stop, and return functions, and variable speed jog for precise control.

- User-friendly software: Provides repeatable and reproducible results for a variety of testing requirements, from simple to complex.

- Variable pressure hydraulic power supply: Delivers pressure on demand, reducing heat generation, increasing oil life, and eliminating the need for water cooling.

- Optional closed-head grip design: Available for additional customization and flexibility.

Models

- 600DX – 600 kN (135,000 lbf) capacity

Typical Applications

- Metals: Bar, plate, pipe, tube, rebar, and structural components

- Fasteners

- Wire rod

- Composites

Standards

DX Models conform to several international standards, including (but not limited to):

- ASTM: A370, A615, C39, C109, E4, E8, E9, E290, F606

- ISO: 6892-1, 6892-2, 7438, 7500-1, 9513, 15630-1

- BS: 4449

- EN: 10002-1, 10002-2

- JIS: Z2241, Z2248

The DX Models are highly versatile, offering superior performance and durability for a wide range of materials and applications.

The HDX Series

The HDX Models are designed for high-capacity tension, compression, bend/flex, and shear testing, featuring a dual test space and an extended test stroke. Built with operator safety as a priority, these frames incorporate high-quality materials, components, and expert craftsmanship, making them ideal for testing metals, wire, fasteners, concrete, and wood.

Features and Benefits

- Dual test space design: Enhances safety and efficiency by allowing users to switch between tension and compression testing without removing heavy fixtures.

- Open-front grip design: Improves operator safety and throughput, allowing a limited number of jaw faces to cover a wide range of specimen sizes.

- Long test stroke: Accommodates a variety of test fixtures and applications, including rebar bend tests.

- Ergonomic handset: Features a fine position adjustment wheel, two programmable softkeys, start, stop, and return functions, and variable speed jog for enhanced control.

- User-friendly software: Ensures repeatable and reproducible results for a wide range of testing needs, from basic to advanced.

- Variable pressure hydraulic power supply: Delivers pressure on demand, reducing heat generation, extending oil life, and eliminating the need for water cooling.

- Optional closed-head grip design: Available for increased flexibility in testing applications.

Models

- 1000HDX – 1,000 kN

- 1500HDX - 1,500 kN

Typical Applications

- Metals: Bar, plate, pipe, tube, rebar, and structural components

- Wire: Rod, strand

- Fasteners

- Concrete: Cubes, cylinders, and beams

- Wood

Standards

HDX Models conform to numerous international standards, including (but not limited to):

- ASTM: A370, A615, C39, C109, E4, E8, E9, E83, E290, F606

- ISO: 6892-1, 6892-2, 7438, 7500-1, 9513, 15630-1

- BS: 4449

- EN: 10002-1, 10002-2

- JIS: Z2241, Z2248

The HDX Models are engineered for superior performance in demanding environments, providing reliable results across a wide range of material testing applications.

The KPX Series

The KPX Models are designed for high-capacity tension, compression, bend/flex, and shear testing, featuring an ultra-large single test space and adjustable crosshead options. Prioritizing operator safety, these frames are constructed with high-quality materials, components, and expert craftsmanship, making them ideal for testing metals, wire, concrete, fasteners, wood, and composites.

Features

- Adjustable crosshead options: Allow the test space to be adapted for a wide variety of test specimens, applications, and accessories.

- Linear guidance system: Ensures precise alignment of the load string throughout the actuator's entire stroke.

- Co-axially mounted encoder: Accurately measures actuator travel at the center of the load string for greater accuracy.

- Ergonomic working height and controls: Improve operator productivity and comfort.

- Long stroke, high-speed actuator: Supports both tension and compression testing applications.

- Ergonomic handset: Equipped with a fine position adjustment wheel, two programmable softkeys, start, stop, and return functions, and variable speed jog for enhanced control.

- User-friendly software: Delivers repeatable and reproducible results for both basic and sophisticated testing needs.

Models

- 1500KPX: 1,500 kN (337,500 lbf)

- 2000KPX: 2,000 kN (450,000 lbf)

Typical Applications

- Metals: Bar, plate, pipe, tube, rebar, and structural components

- Wire: Rod, strand

- Concrete

- Fasteners

- Wood

- Composites

Standards

KPX Models conform to several international standards, including (but not limited to):

- ASTM: A370, A615, C39, C109, E4, E8, E9, E83, E290, F606

- ISO: 6892-1, 6892-2, 7438, 7500-1, 9513, 15630-1

- BS: 4449

- EN: 10002-1, 10002-2

- JIS: Z2241, Z2248

The KPX Models are engineered for superior performance in various high-capacity material testing applications, offering reliability and versatility across a wide range of industries.